A hydraulic press generally consists of a machine body, power system, and hydraulic system. The machine body typically refers to the frame of the hydraulic press, moving parts, and other guiding devices; the power system refers to the device that provides power in the hydraulic press, which is the power source; the hydraulic system is driven by the power system, controls the direction and pressure of the hydraulic fluid to achieve the working process of the hydraulic press, and is a more complex system in the hydraulic press.

The hydraulic system consists of power components, actuators, control components, and auxiliary components.

-Power components: hydraulic pump

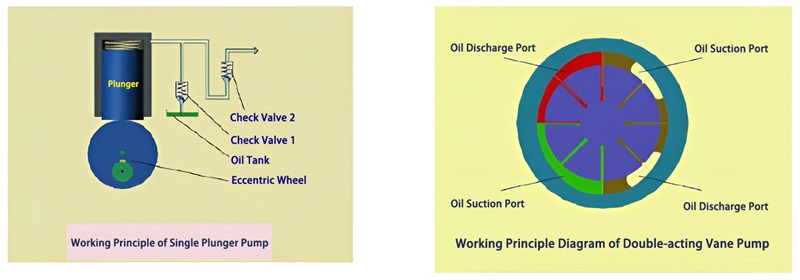

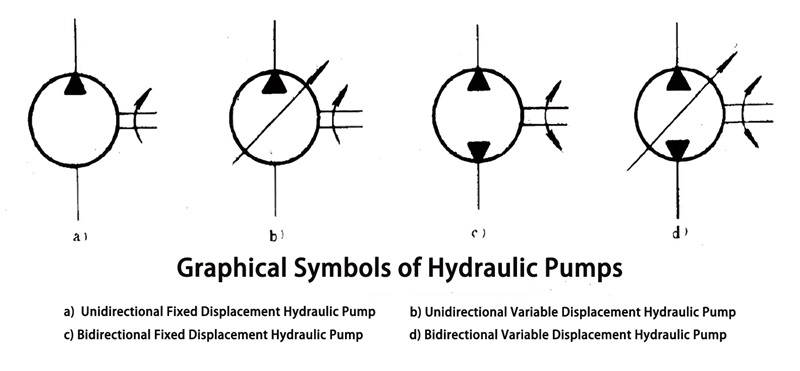

The hydraulic pump is the power component of the hydraulic system, converting the mechanical energy input by the prime mover into pressure energy output to provide pressure oil to the actuators. There are several forms of hydraulic pumps such as gear pumps, piston pumps, vane pumps, and screw pumps.

-Actuators: hydraulic cylinder or hydraulic motor

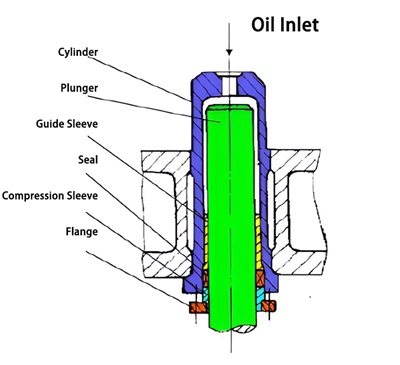

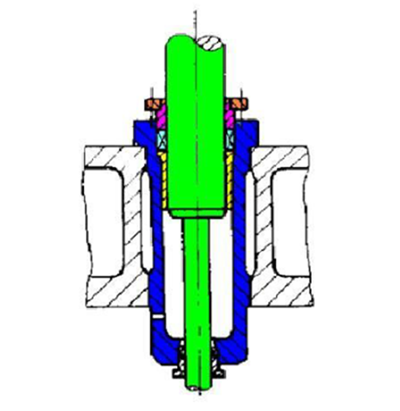

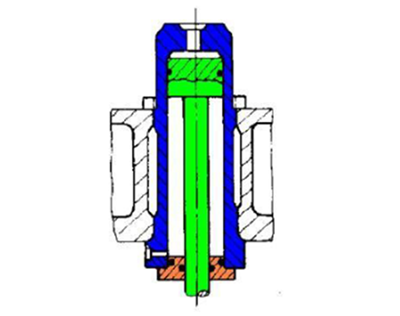

The function of the hydraulic cylinder is to convert the pressure energy of the liquid into mechanical energy, driving the working mechanism in linear or swinging motion. The input of the hydraulic cylinder is the pressure and flow rate of the oil, and the output is force and speed. It has a simple structure, reliable operation, high power transmission, and high control accuracy, with common structural forms such as piston type and plunger type.

1. Plunger type hydraulic cylinder: widely used in working cylinders, return cylinders, working table moving cylinders, and balance cylinders, etc. It has a simple structure and is easy to manufacture, but it can only act in one direction, and reverse movement needs to be implemented using a return cylinder.

2. Differential plunger hydraulic cylinder: this hydraulic cylinder has strong guiding and bearing capacity, can be used as a return cylinder mounted on the upper beam, and is easily connected to the moving beam.

3. Piston type hydraulic cylinder: widely used in small and medium hydraulic presses. The piston type hydraulic cylinder can act in two directions, both completing the working stroke and achieving the return stroke, but the entire inner surface of the cylinder needs to be processed, with high precision requirements and a complex structure.

A hydraulic motor refers to a device that outputs rotational motion, converting the hydraulic energy provided by the hydraulic pump into mechanical energy. Compared to a hydraulic pump, a hydraulic motor has the opposite function, similar types, and mutually reverse principles.

- Control Components: Various control valves

Control valves are used to control the pressure, flow, and direction of fluid in a hydraulic system in order to meet the requirements for force, speed, and motion direction of the actuator. Depending on their purpose, valves can be divided into directional control valves, pressure control valves, and flow control valves, which can be operated manually, mechanically, hydraulically, pneumatically, or electro-hydraulically.

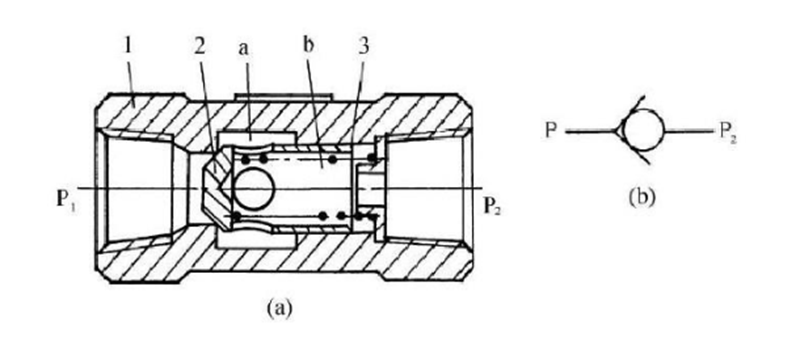

1.Directional Control Valve - Check Valve

Also known as a check valve, as the name suggests, it only allows fluid to flow in one direction and prevents reverse flow (acts as a check). It can be used at the outlet of a hydraulic pump to prevent backflow in the system, or to separate the connections between different hydraulic circuits to prevent interference; it can also be used as a bypass valve, connected in parallel with other types of hydraulic valves to create a combination valve.

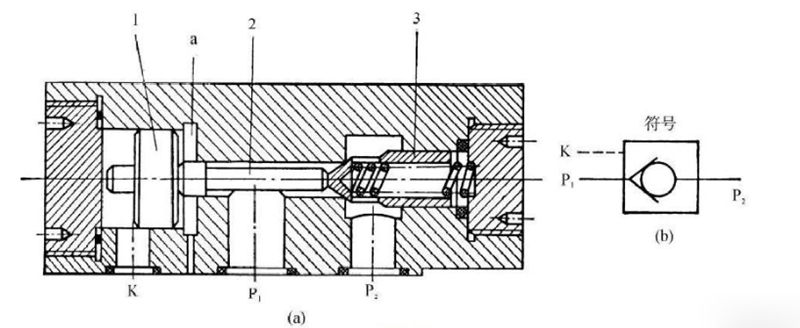

2. Directional Control Valve - Hydraulic Check Valve

Allows fluid to flow in one direction, with the reverse opening controlled by hydraulic control. It can be used as a two-way on-off valve or as a pressure retaining valve, and two hydraulic check valves can be used to form a hydraulic lock.

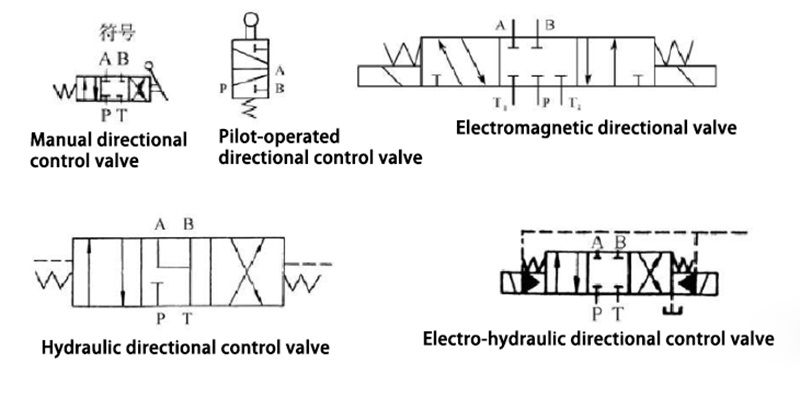

3. Directional Control Valve - Directional Valve

A directional valve changes the position of the valve spool relative to the valve body, opening or closing the oil passage, or changing the direction of oil flow to start, stop, or change the direction of movement of the hydraulic actuator.

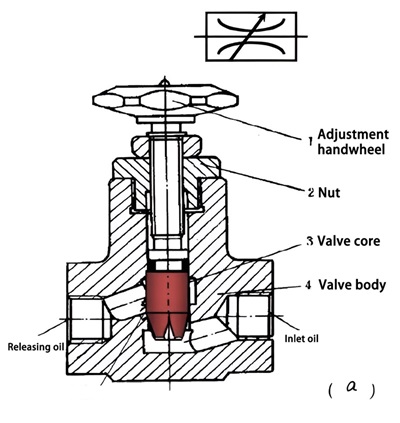

4. Flow Control Valve - Throttle Valve

Fluid flows into the valve through the inlet port and exits through the outlet port after passing through the throttle port. By rotating the adjusting handwheel, the valve spool generates axial displacement, changing the opening size of the throttle port. The higher the valve spool moves up, the larger the opening size.

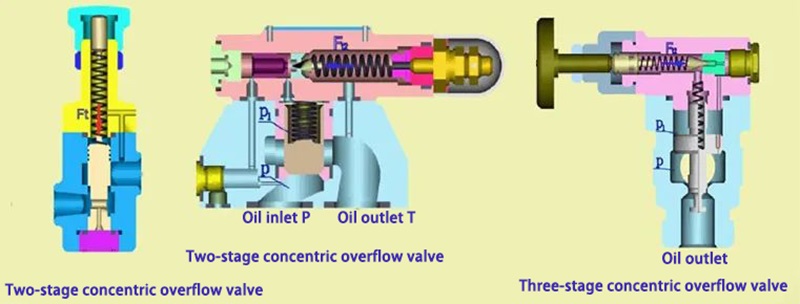

5. Pressure Control Valve - Relief Valve

The relief valve maintains constant pressure in the hydraulic system by allowing fluid to overflow, ensuring pressure regulation, adjustment, and limitation. It plays two main roles: maintaining constant system pressure during continuous overflow, for pressure regulation and overflow; and preventing hydraulic system overload as a safety protection. It can be direct-acting or pilot-operated.

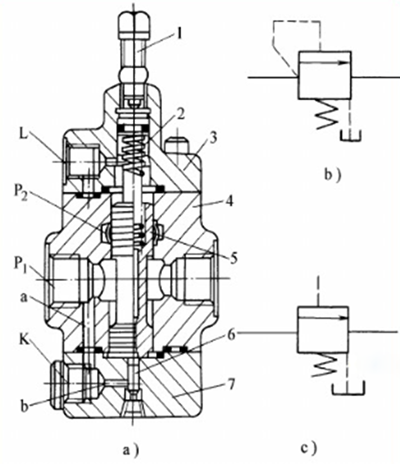

6. Pressure Control Valve - Sequence Valve

The sequence valve uses hydraulic pressure as a control signal to control the opening and closing of the oil passage, ensuring that multiple actuating elements in the hydraulic system operate in a certain sequence. It generally does not control system pressure.

Three main differences between sequence valves and relief valves are:

(1) The inlet pressure of a relief valve remains basically unchanged in the flow state, while a sequence valve generally does not control system pressure;

(2) The outlet of a relief valve is directly connected to the oil tank, while a sequence valve requires a separate oil drain port connected to the oil tank;

(3) The outlet of a relief valve must return to the oil tank, while the outlet of a sequence valve can be connected to a load.

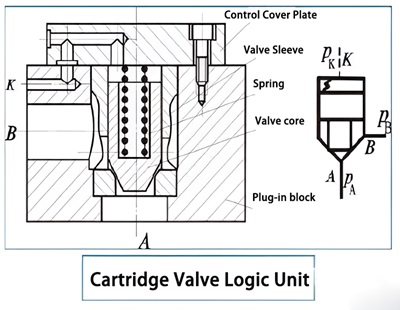

7. Cartridge Valve

A cartridge valve, also known as a logic valve, is a relatively new type of hydraulic component with characteristics such as high flow capacity, good sealing performance, sensitive action, and simple structure. As a result, it is mainly used in systems with high flow rates or systems with high sealing performance requirements.

A cartridge valve consists of a control cover, a cartridge unit (composed of a valve sleeve, spring, valve spool, and seals), a cartridge block, and a pilot control valve (such as a two-way three-port solenoid directional valve).

Sealing device

Common sealing materials:rubber: oil-resistant rubber, fabric-reinforced rubber, polyurethane rubber

Plastics: PVC, PTFE, nylon 6, nylon 1010, bronze

Seal shapes: V-shaped, U-shaped, Y-shaped, Yx-shaped, O-shaped, H-shaped, as well as triangular, rectangular, trapezoidal, etc.

Characteristics of sealing materials:Good chemical stability within a certain temperature range, insoluble in working fluid, no mutual corrosion or adhesion when in contact with metals; within a certain time range, do not soften or harden, good elasticity, not easy to deform, good wear resistance, low friction coefficient, easy to manufacture, low cost.

1.Structure and characteristics of hydraulic system· XIRO (xiromachinery.com)

3.Dual-cylinder four-column hydraulic press synchronous control system· XIRO (xiromachinery.com)

XIRO-electric servo press/XIRO-hydraulic press/XIRO-mechanical powder compacting press

XIRO, an automated machine manufacturer, 24-hour response factory, with a professional engineering team 24 hours online technical service. All machines are CE certified, come with a 2-year warranty, and lifetime service. With 20+ years rich production experience, our equipment is exported to more than 60 countries. We provide customizable press machines and comprehensive productivity solutions, ensuring it's the most competitive, accurate solution to any assembly requirement! XIRO wishing you prosperity!