Two basic forms: pump direct drive, pump-accumulator drive.

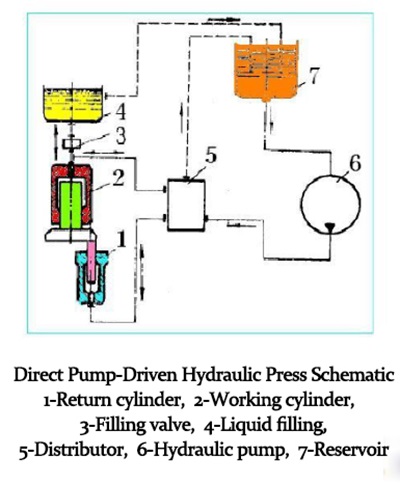

-Pump direct drive:

High-pressure liquid is directly pumped into the working cylinder or return cylinder by the hydraulic pump. During the working stroke, the high-pressure liquid pumped out by the hydraulic pump 6 enters the working cylinder 2 through the distributor 5, while the liquid in the return cylinder 1 is discharged into the reservoir 7 through the distributor; during the return stroke, the high-pressure liquid pumped out by the hydraulic pump enters the return cylinder through the distributor, and most of the liquid in the working cylinder flows out through the filling valve 3 into the filling tank 4.

Characteristics of pump direct drive hydraulic press:

(1) The speed of the hydraulic press's moving crossbeam depends on the pump's flow rate, not on the resistance to deformation of the forging process.

(2) The power consumed by the high-pressure pump (pressure x flow rate) is equivalent to the power of the hydraulic press's work (velocity x force), meaning the power consumed by the pump depends on the deformation resistance of the forged workpiece.

(3) Since the speed of the moving crossbeam remains constant during the working stroke, and the hydraulic pressure matches the resistance of the forging process, the constant speed and changing pressure can be used as signals for the operation of the distributor, achieving automatic control of the hydraulic press.

Advantages: low initial investment, small footprint, and easy maintenance.

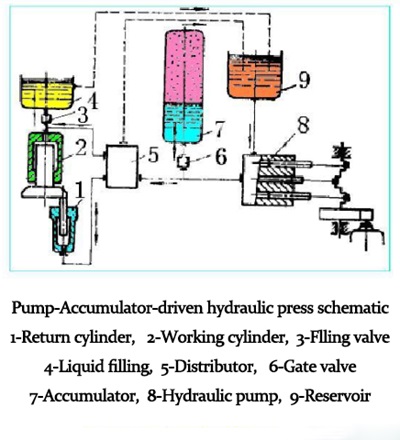

-Pump-accumulator drive:

During the working stroke, the high-pressure liquid pumped out by the hydraulic pump 8 and the high-pressure liquid stored in the accumulator 7 both enter the working cylinder 2 through the distributor 5, while the liquid in the return cylinder 1 is discharged into the reservoir 9 through the distributor, ensuring the maximum supply of liquid required by the hydraulic press for a certain period of time.

In other processes, when the high-pressure liquid required by the hydraulic press is less than the supply of liquid by the hydraulic pump, or when high-pressure liquid is not needed, the excess liquid pumped out by the hydraulic pump is stored in the accumulator, serving as energy storage.

In addition, the accumulator also plays a role in stabilizing pressure and providing a more uniform supply of liquid.

Characteristics of pump-accumulator transmission hydraulic press:

(1) Energy consumption is directly proportional to the stroke size of the hydraulic press, and is unrelated to the resistance of the forging.

(2) The working stroke speed of the hydraulic press depends on the resistance of the forging, with higher resistance resulting in slower speed and lower resistance resulting in faster speed.

Advantages: The supply hydraulic pressure of the hydraulic press is basically maintained within the pressure fluctuation range of the accumulator.

Applicable range of two forms:

Generally, a single medium-sized hydraulic press should adopt direct pump drive, which is most suitable for pressing processes that require a large amount of energy.

In recent years, considering the advantages of direct pump drive such as constant speed, low average power consumption, and the ability for the hydraulic press to achieve maximum speed at maximum pressure, along with the use of high-pressure high-flow variable pumps, high-pressure high-flow slide valve directional valves, servo valves, cartridge valves, etc., direct pump drive may gradually replace the widely used pump-accumulator transmission form in large hydraulic presses.

1.What is a hydraulic system?· XIRO (xiromachinery.com)

3.Dual-cylinder four-column hydraulic press synchronous control system· XIRO (xiromachinery.com)

XIRO-electric servo press/XIRO-hydraulic press/XIRO-mechanical powder compacting press

XIRO, an automated machine manufacturer, 24-hour response factory, with a professional engineering team 24 hours online technical service. All machines are CE certified, come with a 2-year warranty, and lifetime service. With 20+ years rich production experience, our equipment is exported to more than 60 countries. We provide customizable press machines and comprehensive productivity solutions, ensuring it's the most competitive, accurate solution to any assembly requirement! XIRO wishing you prosperity!

|

|

|