I. Calculation Formula

1. Hydraulic cylinder area (cm2)

A=πD2/4

Note: D is the effective piston diameter of the hydraulic cylinder (cm)

2. Relationship between hydraulic cylinder speed (cm/min) and flow rate (L/min)

V=Q/A

Note: Q is the flow rate (L/min), A is the effective working area of the hydraulic cylinder piston (cm2)

3. Relationship between differential speed V1 and non-differential speed V0 of the hydraulic cylinder rodless cavity

V1=V0A1/(A1-A2)

Note: A1 is the effective working area of the hydraulic cylinder rodless cavity (cm2), A2 is the effective working area of the hydraulic cylinder rod cavity (cm2)

4. Hydraulic cylinder output thrust (kgf)

F=(P1×A1)-(P2×A2)

Note: P1 is the pressure in chamber A1 (kgf/cm2), P2 is the pressure in chamber A2 (kgf/cm2), A1 and A2 are the effective working areas of the hydraulic cylinder inlet and return cavities (cm2)

5. Pump or motor flow rate (L/min)

Q= q×n/1000

Note: q is the geometric displacement of the pump or motor (mL/r), n is the speed (rpm)

6. Flow rate through the throttle (Q) (L/min)

Q=8a(10△P) 1/2

Note: a is the flow area of the throttle (cm2), △P is the pressure difference before and after the throttle (MPa)

7. Pump or motor torque (N.m)

T = q × p / 20π

8. Required hydraulic power (kw)

P = Q × p / 612

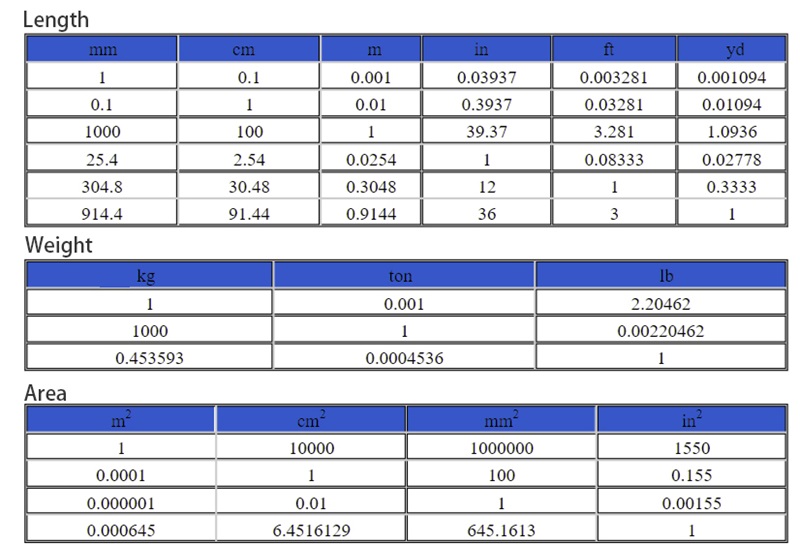

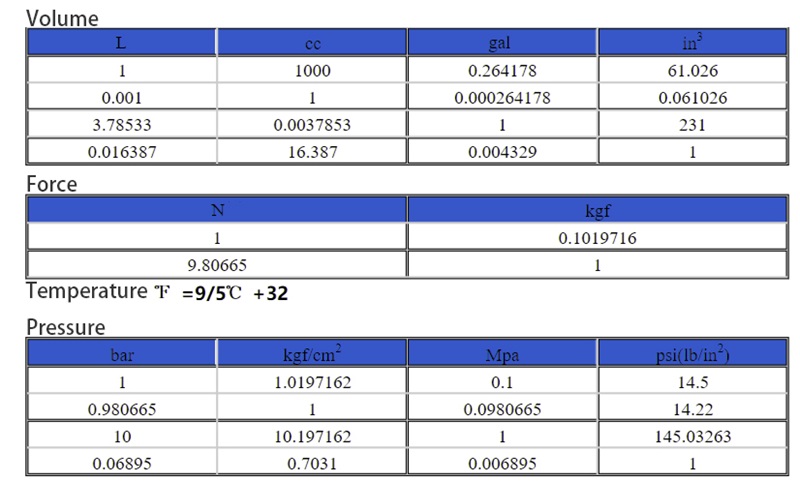

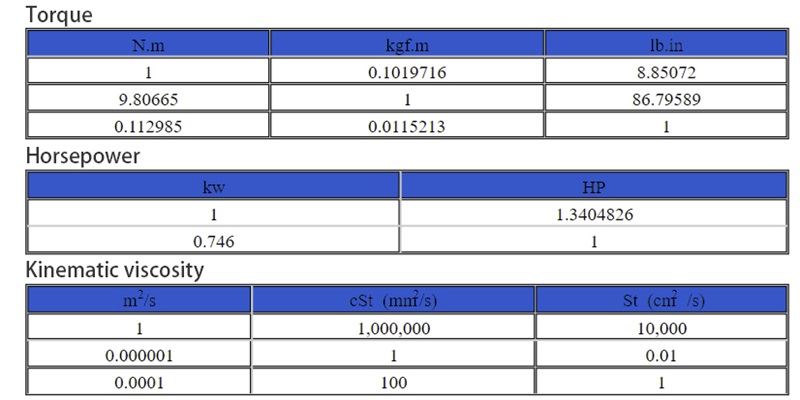

II. Unit conversion

XIRO-electric servo press/XIRO-hydraulic press/XIRO-mechanical powder compacting press

XIRO, an automated machine manufacturer, 24-hour response factory, with a professional engineering team 24 hours online technical service. All machines are CE certified, come with a 2-year warranty, and lifetime service. With 20+ years rich production experience, our equipment is exported to more than 60 countries. We provide customizable press machines and comprehensive productivity solutions, ensuring it's the most competitive, accurate solution to any assembly requirement! XIRO wishing you prosperity!

|  |  |