1. Definition of Hydraulic System Crawling Phenomenon

The crawling phenomenon in a hydraulic system refers to intermittent flow disruptions of the working medium (hydraulic fluid) when it flows into or out of the actuating elements (hydraulic motors or cylinders). This occurs due to unstable flow and flow rates in the hydraulic pipelines, which affects the normal operation of the actuating mechanism, causing it to alternate between sliding and stopping. This abnormal pulsation state is commonly referred to as "crawling."

2. Root Causes of the Crawling Phenomenon

2.1 Mathematical Model of the Crawling Phenomenon

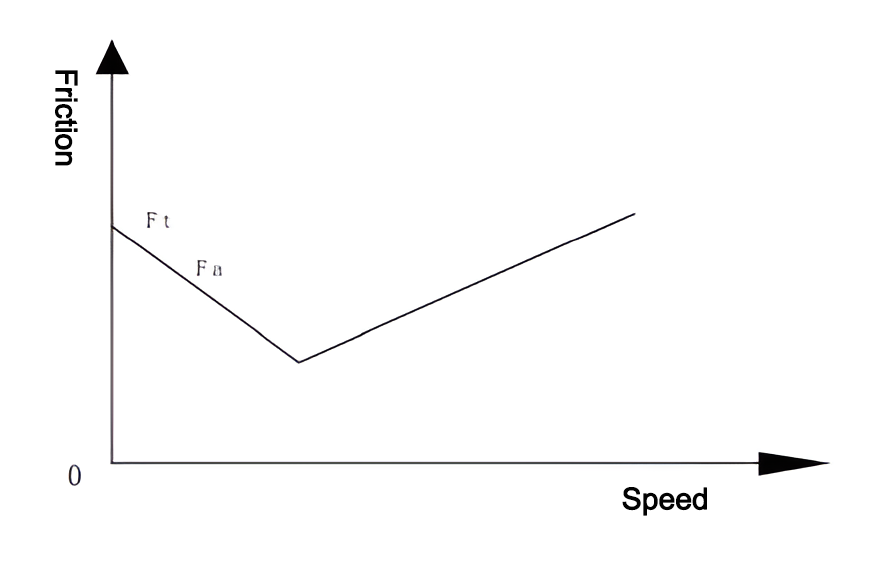

The crawling phenomenon in hydraulic systems often occurs during low-speed operation of hydraulic cylinders or motors. To facilitate mathematical analysis and numerical calculations, the motion process and characteristics of the crawling phenomenon in hydraulic systems can be simplified into a linear transmission system. The relationship between the frictional force on the moving components and their velocity is linearly simplified. The mathematical model (as shown in Image 1) depicts the expression of the motion state of the driven component.

Image 1: The linear relationship between friction and motion in a hydraulic system

By analyzing the relationship between the speed of the driven component and various factors in the hydraulic system, with other variables fixed, the influence of specific factors on the speed can be identified.

2.2 Various Factors Causing the Crawling Phenomenon

Crawling in hydraulic transmission systems is not an accidental occurrence. There are multiple causes of crawling in hydraulic systems, and addressing these requires careful observation and thoughtful analysis. Based on the characteristics of hydraulic systems and extensive research on crawling, the main causes of crawling are summarized as follows:

2.2.1 Changes in Frictional Resistance Causing Crawling

Variations in the frictional resistance between sliding components in the hydraulic system are the fundamental cause of crawling.

Several factors influence system friction, such as differences in the friction coefficients of materials used for hydraulic components. Proper material selection is crucial in managing frictional effects. Materials with smaller differences between static and dynamic friction coefficients make the frictional variation smoother, while large friction changes can easily lead to crawling.

Additionally, improper scraping or grinding during manufacturing may cause uneven contact surfaces between sliding components, leading to inadequate lubrication. This can also be caused by the selection of inappropriate or low-quality lubricants, poor lubricant channel design, or insufficient lubrication performance. These factors lead to inconsistent lubrication conditions between sliding components. In extreme cases, metal parts may come into direct contact, breaking the lubrication film and causing partial or complete dry friction. This uneven frictional force may trigger the crawling phenomenon.

2.2.2 Air in the Hydraulic System Causing Crawling

When air enters the hydraulic cylinder, part of it dissolves into the hydraulic oil, while the remaining part forms floating bubbles suspended in the oil. Since air is compressible, this gives the hydraulic oil noticeable compressibility, which slows down the system’s pressure increase, preventing it from reaching the specified pressure in the expected time. This reduces the overall rigidity of the hydraulic system, and in severe cases, can cause the system to experience crawling.

Typically, no air should be present inside a sealed hydraulic cylinder, but improper maintenance or operation can lead to air entering the cylinder. Since air does not fully dissolve in hydraulic oil, small air bubbles form and remain suspended in the oil.

If air is mixed inside the cylinder, when the system starts to provide pressurized oil, the compressibility of the air causes it to act as an accumulator, absorbing part of the pressure and slowing down the rate of pressure increase.

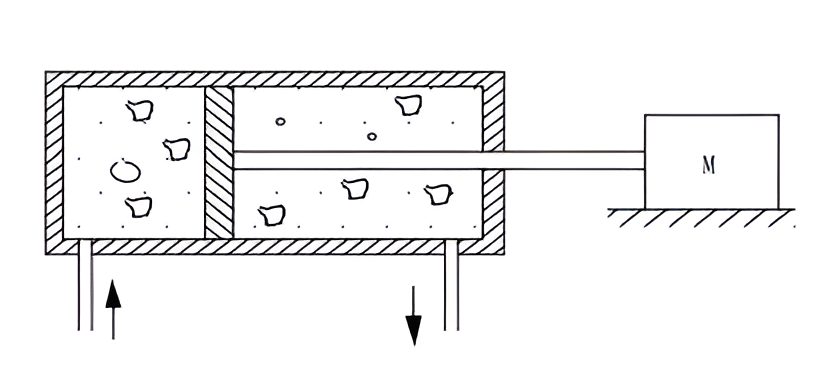

Once the system’s oil pressure exceeds the maximum static friction of the piston, the piston overcomes the friction and starts to move. At this point, the resistance decreases to sliding friction, and the pressure stored in the remaining air pushes the piston forward. As the pressure stored in the air is released, the pressure on the piston gradually decreases, so the piston’s forward speed also decreases. The cylinder’s pressure rapidly drops, and when it falls below the minimum pressure required to overcome sliding friction, the piston stops moving. This process is illustrated in Image 2.

Image 2: Release of energy stored in the air in the cylinder

Since the system continues to supply pressurized oil, the air inside the cylinder is compressed further, and the pressure in the cylinder slowly rises again as oil is continuously injected. When the cylinder’s pressure again exceeds the maximum static friction resistance of the piston, the piston surges forward once more. This cycle repeats, resulting in the crawling phenomenon.

This is a direct consequence of the compressibility of the air inside the cylinder affecting the resistance changes. In other situations, such as when the hydraulic cylinder is under a load, the load size may fluctuate, making it impossible to maintain a constant pressure. Therefore, as long as there is excess air in the cylinder, crawling is likely to occur during system operation.

2.2.3 Wear of Hydraulic Components Causing Crawling

In a hydraulic system, severe wear of internal parts of hydraulic cylinders or motors damages the original dimensions and shapes of the components. This results in significant errors in the designed fit, and the clearance between sliding surfaces increases. Such changes reduce or fluctuate the system’s output flow, which is a fundamental cause of pressure fluctuations and insufficient pressure output, leading to crawling.

The wear of internal moving parts of hydraulic cylinders and valves can also cause the hydraulic system to crawl. For example, prolonged abnormal friction between the piston and the inner diameter of the cylinder tube can cause significant wear, leading to a gap between the two that far exceeds normal operating limits. Excessive clearance can easily cause internal leakage, reducing the pressure differential between the two chambers of the hydraulic cylinder. This greatly decreases thrust, and during low-speed operation, the lack of driving force combined with continuous variations in static and dynamic friction can easily result in crawling.

For certain hydraulic system valve components, prolonged normal or abnormal wear increases the clearance between parts, allowing low-pressure oil and high-pressure oil to mix. This leads to system pressure instability, which is particularly prone to causing crawling during low-speed operation.

2.2.4 Characteristics of Hydraulic Oil Causing Crawling

Compared to air, the compressibility of hydraulic oil is already very low. However, when the internal space of the hydraulic cylinder is large, such as in large hydraulic presses, and the pressure is high, the large volume of hydraulic oil makes the compressibility of the oil more apparent. This reduces the rigidity of the hydraulic system, similarly to when air enters the system, making it prone to crawling.

If the hydraulic oil contains contaminants, it may block the control orifices in hydraulic valves, resulting in insufficient oil supply and causing crawling. If the throttle or damping orifice in the control valve is small, contaminants in the oil can easily adhere to these orifices, partially blocking the oil flow path. This hinders the smooth flow of oil in the hydraulic system, making the movement of the slide valve less responsive and reducing the flow through the throttle valve. This increases the pressure differential in the system, leading to significant pressure fluctuations. The pulsating pressure, which alternates between high and low, may dislodge the contaminants from the throttle or damping orifice, allowing the oil flow to increase again. This cycle of blockage and release causes repeated flow fluctuations, which can result in hydraulic system crawling.

2.2.5 Other Factors Affecting Hydraulic Crawling

(1) Damping in the System

The damping level within a hydraulic system is crucial for ensuring smooth operation. If the system’s damping is too low, the system’s ability to absorb vibrations is significantly reduced. This may lead to severe vibrations during operation, increasing friction variations between sliding components, which can easily lead to crawling.

(2) Mass of Movable Components in the System

According to the law of inertia, the greater the mass of an object, the larger its inertia. For objects moving along the same surface quality, a greater mass results in greater friction. Similarly, in a hydraulic system, the greater the mass of the moving components, the greater the friction they encounter during movement, making the system more prone to crawling.

Besides the causes of hydraulic crawling described above, many other conditions can also lead to crawling. In actual operation, the causes of crawling should be analyzed based on the specific circumstances, allowing for timely and effective control measures to be taken to ensure the normal operation of the hydraulic system.

1.What is a hydraulic system?· XIRO (xiromachinery.com)

XIRO-electric servo press/XIRO-hydraulic press/XIRO-mechanical powder compacting press

XIRO, an automated machine manufacturer, 24-hour response factory, with a professional engineering team 24 hours online technical service. All machines are CE certified, come with a 2-year warranty, and lifetime service. With 20+ years rich production experience, our equipment is exported to more than 60 countries. We provide customizable press machines and comprehensive productivity solutions, ensuring it's the most competitive, accurate solution to any assembly requirement! XIRO wishing you prosperity!