1. Basic Principles of Servo Motor Controller Parameter Adjustment

1.1 Overview of the Servo Motor Controller

A servo motor controller is a high-precision, high-performance motor driver that can accurately control motor speed, position, and torque according to input control signals. Servo motor controllers are widely used in automation equipment, robotics, CNC machinery, and other fields.

1.2 Importance of Parameter Adjustment

Parameter adjustment is crucial for the optimal performance of the servo motor controller. Proper adjustment allows for optimization of the system’s dynamic response, stability, precision, and efficiency.

1.3 Basic Principles of Parameter Adjustment

Systemic Principle: When adjusting parameters, consider the stability and performance of the entire system rather than focusing on individual components.

Gradual Adjustment Principle: Parameters should be adjusted gradually, observing system responses after each change to ensure accuracy.

Accumulated Experience Principle: Parameter adjustments should be based on real-world applications and accumulated experience, continuously refining the settings.

2. Common Servo Motor Controller Parameters and Adjustment Methods

2.1 Basic Parameters

Gain: Determines the system's response speed and stability. Excessive gain may lead to oscillations, while insufficient gain could slow the response.

Integral Time: Affects the steady-state error of the system. Too long an integral time may slow system response, while too short may cause oscillations.

Derivative Time: Helps control overshoot and oscillations in the system. Proper derivative time can improve system stability.

2.2 Adjustment Steps

① Initialization: Before making adjustments, reset the controller to factory settings to ensure the accuracy of adjustments.

② Gain Adjustment: Begin by adjusting the gain, monitoring the system’s dynamic response. Gradually increase the gain until oscillations appear, then reduce it slightly for optimal response speed and stability.

③ Integral Time Adjustment: After setting the gain, adjust the integral time gradually until the system’s steady-state error is within acceptable limits.

④ Derivative Time Adjustment: Finally, adjust the derivative time, gradually increasing it until overshoot and oscillations are effectively suppressed.

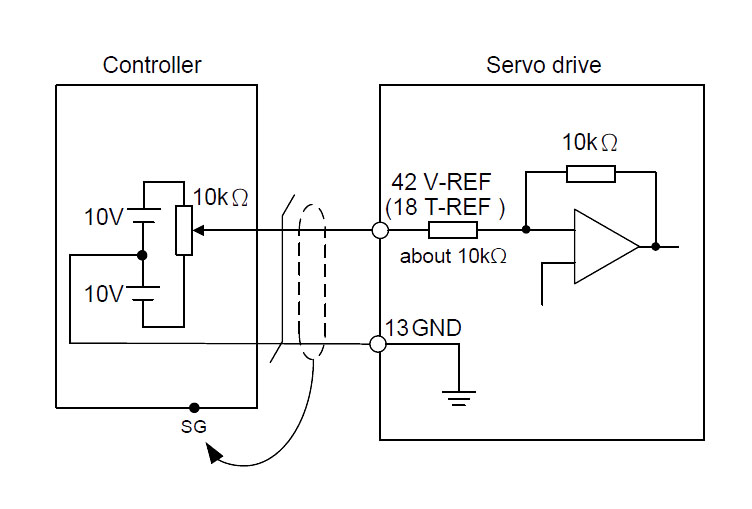

Speed,Input of Torque Analog Command

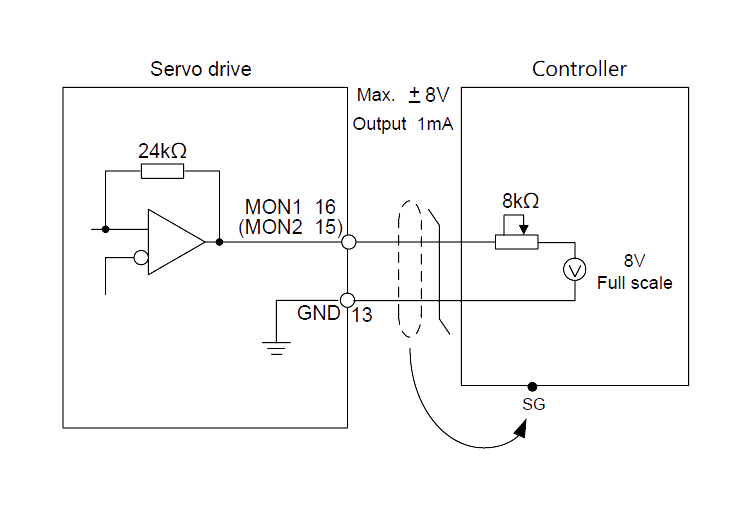

Analog Monitor Output MON1,MON2

2.3 Key Considerations

Safety First: Ensure the safety of operators and equipment during parameter adjustment.

Data Backup: Back up current parameter settings before adjustments to facilitate quick recovery if issues arise.

Record the Adjustment Process: Keep detailed records of each adjustment, including parameter values and system responses, for analysis and further optimization.

3. Case Study Analysis of Practical Application

3.1 Case Background Consider an automated production line where servo motor controller parameters need adjusting to enhance line efficiency and stability.

3.2 Parameter Adjustment Process

① Problem Diagnosis: Diagnose issues in the production line, such as speed instability or inadequate positional accuracy.

② Parameter Adjustment: Based on the diagnosis, choose the appropriate parameters to adjust. For instance, if speed is unstable, prioritize adjusting the gain and derivative time.

③ Performance Evaluation: After each adjustment, evaluate the results. If performance is unsatisfactory, continue adjusting other parameters or fine-tuning the current ones.

④ Optimization Iteration: Parameter adjustment is an iterative optimization process, requiring continuous refinement until the desired performance is achieved.

3.3 Result Analysis

Parameter adjustments led to significant improvements in production line efficiency and stability, such as reduced speed fluctuations, improved positional accuracy, and lower equipment failure rates.

Adjusting the parameters of a servo motor controller is a complex, detailed process requiring real-world applications and experience. Through careful adjustment, it is possible to significantly enhance the dynamic response, stability, accuracy, and efficiency of servo systems.

XIRO-electric servo press/XIRO-hydraulic press/XIRO-mechanical powder compacting press

XIRO, an automated machine manufacturer, 24-hour response factory, with a professional engineering team 24 hours online technical service. All machines are CE certified, come with a 2-year warranty, and lifetime service. With 20+ years rich production experience, our equipment is exported to more than 60 countries. We provide customizable press machines and comprehensive productivity solutions, ensuring it's the most competitive, accurate solution to any assembly requirement! XIRO wishing you prosperity!