The dropper seatpost is a core functional component of modern mountain bikes, and its reliability directly impacts rider safety and handling experience. According to industry data, in 2024, seatpost failures accounted for 12.7% of global cycling accidents, with 72% linked to material strength deficiencies or assembly defects. Under extreme conditions (such as continuous impacts on a 10% slope), the seatpost must withstand ≥1200N dynamic loads and complete over 500,000 adjustment cycles.

Dropper Seatpost

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific produc)

1. Material Strength Testing

Case Study: Carbon Fiber Seatpost Fracture

A carbon fiber seatpost from a well-known brand fractured under extreme riding conditions, with measured wall thickness deviations up to ±0.07mm.

XIRO Testing Solution

To ensure consistent and reliable material strength for mountain bike dropper seatposts, XIRO applied electric servo press technology with precise control:

Static Load Test: According to ISO 4210-6:2021 standards, a vertical static load of 1200N was applied for 30 seconds.

Dynamic Load Test: Simulating ±25mm stroke and 50,000 cycle dynamic impacts (complying with GB/T 30032-2015 dynamic testing standards).

Abnormality Diagnosis

Wall thickness deviation: Traditional hydraulic systems exhibited speed fluctuations of ±5mm/s during tubing necking, causing wall thickness tolerance variations of ±0.1mm, increasing stress concentration by 1.8 times.

Material fracture phenomenon: The maximum pre-fracture load capacity was only 950N (below the standard 1200N), with dynamic load dropping to 400N upon fracture.

Lamination defects: Pressure fluctuations ≥15%, interlayer shear strength only 28MPa (design requirement ≥45MPa), microporosity density exceeding 200/cm².

XIRO Solutions

Precise Speed Control: Using servo motor direct-drive ball screw achieving ±0.05mm/s speed accuracy, combined with 0.1μm resolution optical scales, compressing wall thickness tolerance to ±0.02mm.

Accurate Pressure Control: Three-stage gradient pressurization (Contact Pressure 50N → Wetting Pressure 1.5kN → Holding Pressure 3kN), automatically switching at the 6061 aluminum alloy yield point (275MPa).

Real-time Pressure Feedback: Six-axis force sensor (1kHz sampling rate) with PID algorithm to maintain mold pressure fluctuation within ±1.5%.

Results and Benefits

| Metric | Traditional Equipment | XIRO | Improvement |

| Interlayer Shear Strength | 28MPa | 52MPa | +85.7% |

| Thickness Tolerance | ±0.08mm | ±0.02mm | +75% |

| Microporosity Density | 200/cm² | ≤20/cm² | +90% |

| Dynamic Load Capacity | 400N | 1350N | +237.5% |

2. Dynamic Fatigue Testing

Case Study: Hydraulic Dropper Seatpost Leakage

A Taiwanese hydraulic dropper seatpost (max travel 100mm) experienced oil leakage (1.5ml/min) and high-cycle fatigue failures in shaft components, leading to increased annual repair rates.

XIRO Testing Solution

Simulated Riding Conditions: 50-100mm stroke range, dynamic load from 0-1500N, adjustable frequency from 0.5-5Hz.

Trapezoidal Wave Loading: 0.1s ascent/descent, 0.2s hold time, covering 95% of real riding impact scenarios.

Stroke Testing Standard: 15 full-stroke motions per minute; failure criteria: leakage >0.5ml/min or positioning deviation >0.3mm.

Dropper Seatpost Testing

(Source: XIRO )

Abnormality Diagnosis

Oil leakage occurred at 32,000 cycles (leakage rate 1.2ml/min).

Traditional equipment showed ±15% dynamic pressure fluctuation (≤±5% required).

Seal wear rate 0.02mm/10,000 cycles (normal ≤0.008mm/10,000 cycles).

Piston rod hardness HV520, below the required HV580.

XIRO Solutions

Residual Stress Control: Surface residual compressive stress on 6061-T6 aluminum piston rods increased to -220MPa, tripling fatigue life.

Dynamic Compensation Loading: Applying reverse compensation forces during load transition, reducing vibration energy by 80%.

Precise Segmented Pressurization: Seal groove dimensional tolerance controlled within ±0.008mm (IT6 grade).

Early Warning Mechanism: Real-time monitoring of pressure-displacement curves, automatic alarms when seal wear exceeds ±3%.

Results and Benefits

| Metric | Traditional Equipment | XIRO | Improvement |

| Piston Rod Hardness | HV520 | HV575±5 | +10.6% |

| Seal Groove Tolerance | ±0.03mm | ±0.008mm | +73% |

| Dynamic Pressure Fluctuation | ±15% | ±4% | +73% |

| Seal Wear Rate | 0.02mm/10,000 cycles | 0.006mm/10,000 cycles | +70% |

3. Locking Force Testing

Case Study: Anti-Slip Function Failure

A supplier's electric dropper seatpost failed its anti-slip function after 500 adjustment cycles.

XIRO Testing Solution

Static Holding Test: Loading at 0.5mm/s speed to 2000N, holding for 30 seconds, monitoring the force decay curve (nonlinear characteristics with R²=0.76 indicate cumulative damage).

Dynamic Cycle Test: 5Hz alternating load (800-1500N), executing 50,000 cycles, measuring thread wear (standard: displacement hysteresis rate<1.5%).

Abnormality Diagnosis

200ms delay detected during pre-press stage (normal<80ms).

Locking torque decay significant (15N·m to 9N·m), exceeding allowable decay rate.

Thread contact stress peak-valley difference reached 42%.

XIRO Solutions

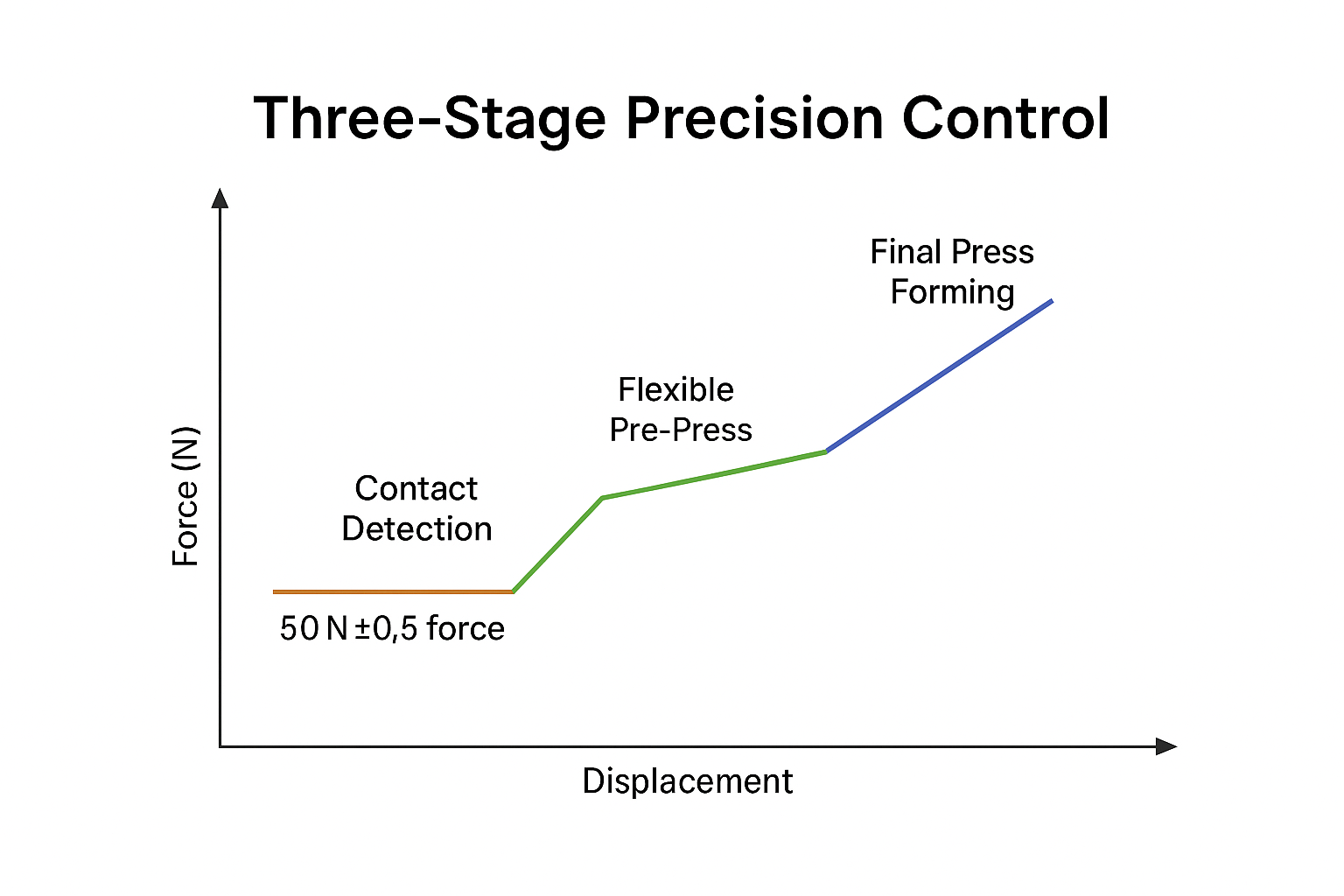

Three-Stage Precision Control

Contact Detection: 50N ±0.5N force, positioning accuracy within ±5μm.

Flexible Pre-Press: 3kN pressure, contact stress dispersion ±3.5%.

Final Press Forming: 8kN final press, 0.05°/s feed rate, thread fill rate ≥98%.

Three-Stage Precision Control

(Source: XIRO )

Real-Time Curve Monitoring: Pressure-displacement real-time analysis, stopping immediately if displacement jump >0.1mm.

Process Data Traceability: Recording up to 1000 sets of assembly data per product for rapid defect tracing.

Results and Benefits

| Metric | Traditional Equipment | XIRO |

| 100-Cycle Torque Retention Rate | 82% | 97% |

| 500-Cycle Torque Retention Rate | 60% | 95% |

| Torque Decay Rate | 0.018N·m/cycle | 0.0015N·m/cycle |

| Thread Surface Roughness | Ra=3.2μm (visible plowing marks) | Ra=0.8μm (uniform plastic deformation) |

| Residual Stress Distribution | +120MPa (microcrack initiation accelerated) | -85MPa (crack propagation suppressed) |

Conclusion

By integrating XIRO Electric Servo Press technology, mountain bike dropper seatposts achieve significant improvements in material strength, fatigue life, sealing system reliability, and locking performance. Precise speed and pressure control, real-time feedback, and dynamic compensation technologies systematically enhance product quality, offering an intelligent, professional solution for seatpost manufacturing.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.