Syringe needle assembly is a critical process in medical device manufacturing, where precision and reliability directly impact product safety and performance. Traditional assembly methods—such as pneumatic presses, hydraulic presses, or manual force insertion—have long-standing limitations. In contrast, electric servo press machines offer a revolutionary solution through advanced force and displacement control. Below is a technical analysis supported by real industry use cases:

Syringe needle assembly

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Challenge 1: Needle and Tube Misalignment Increases Insertion Force or Causes Leakage

Case Study: A leading insulin syringe manufacturer using pneumatic presses to assemble ultra-thin 26G insulin needles (OD 0.45±0.02mm, ID 0.26±0.01mm) reported:

3.5% failure rate due to needle tilt, causing insertion force >0.7N.

0.6% leakage rate due to misalignment.

Measurements revealed:

Needle-to-tube axis deviation often >50μm, max at 112μm.

Radial needle tip runout ≥40μm exponentially increased insertion force.

Root Cause Analysis:

Pneumatic press machines rely on air cylinders with:

Uncontrolled acceleration (>0.5G), creating lateral impact (peak >8N) at needle tip.

Force fluctuation ±10%, making constant-force pressing impossible.

26G needle’s low yield strength (180MPa) makes it prone to elastic bending under such impact.

XIRO Electric Servo Press Solution:

Using a linear servo motor (resolution ≤0.1μm) with precision ball screw and closed-loop PID control to manage displacement-speed-force in real time:

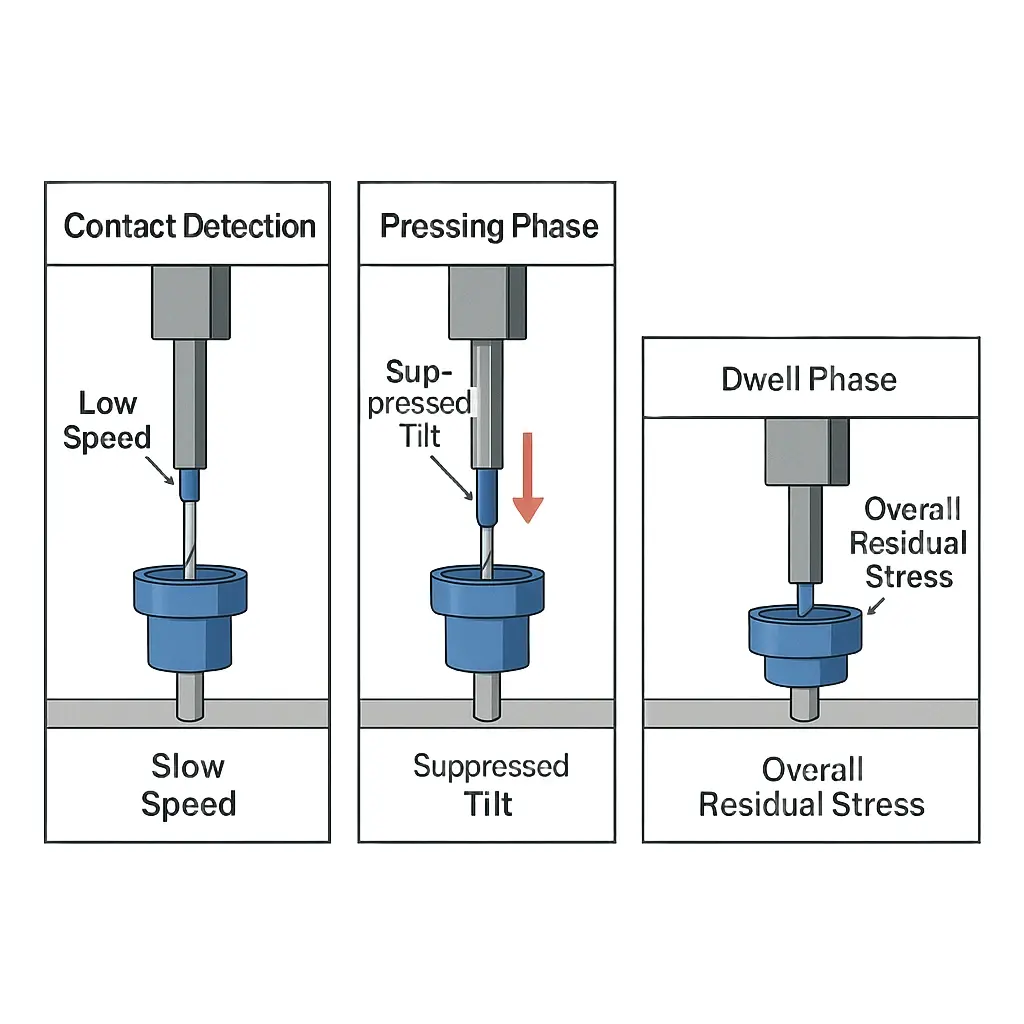

Contact Detection: Ram approaches at 0.5mm/s until a 1N contact force is detected (±0.05N), avoiding tip deformation.

Pressing Phase: Switch to force-control mode (e.g., 15N ±0.2N at 0.1mm/s) to suppress tilt.

Dwell Phase: Hold at 12N ±0.1N for 1.5s to release residual stress.

Real-Time Correction: With visual alignment and built-in tilt sensor (accuracy ±0.01°), XY-axis automatically compensates misalignment.

Results:

Concentricity deviation reduced to ≤10μm.

Insertion force variation range minimized to ±0.1N.

Defect rate dropped below 0.05%.

Challenge 2: Uneven Adhesive Application Causes Needle Drop-Off or Blockage

Case Study: A prefilled syringe manufacturer experienced major rework (costing $23,000 per batch) due to UV adhesive unevenness (±15% tolerance). Testing revealed:

5.2% of products had pull-out force<20N (ISO11040-4 requires ≥25N).

0.3% of needle lumens clogged with overflowed glue, resulting in >5% flow blockage rate (standard ≤2%).

Root Cause Analysis:

UV adhesive is a shear-thinning fluid—viscosity drops as shear rate increases. Pneumatic presses with >5mm/s fixed speed reduce glue viscosity abruptly. During pressing pauses, viscosity recovery lags, resulting in:

Inadequate leveling.

Incomplete wetting of the needle base.

XIRO Electric Servo Press Solution:

Utilizing real-time SSC (Stress-Strain Curve) analysis and differential algorithms to detect fluid flow state and dynamically adjust the press parameters:

Low-Speed Wetting: Ram moves at 0.1mm/s into adhesive layer, holding for 0.8s to improve surface wetting.

Variable-Speed Pressing: Once pressure gradient dP/dS > 0.5N/mm, auto-accelerate to 1mm/s to enhance glue spread.

Curing Dwell: Maintain 12N ±0.2N for 5s at target position for uniform curing.

Parameter Control: All values configurable via recipe management system.

Results:

Adhesive thickness CV<5%.

Pull-out force standard deviation reduced from ±4N to ±0.8N.

Clogging rate reduced to 0.

Challenge 3: Over-Pressing Damages Sealing Surface or Reduces Needle Tip Toughness

Case Study:While assembling 25G safety needles, a manufacturer using pneumatic presses encountered:

3.2% of polycarbonate needle seats had seal surface dents (≥10μm), leading to a 0.4% leakage rate >0.15mL/min (ISO7886-1 requires ≤0.1mL/min).

0.55% of needle tips (316 stainless steel) showed curling (bend angle >5°) due to >30N impact force—causing 0.7% clinical failure rate and costly product recalls.

Root Cause Analysis:

Pneumatic presses rely on mechanical stoppers or pressure switches, which respond in >20ms.

When contact time<2ms, instantaneous="" stress="">95MPa—exceeding yield strength.

Burrs or dimensional outliers can cause impact >200% of preset force.

Mechanical stoppers deform 0.05–0.1mm—insufficient for high-tolerance parts.

No peak pressure data recorded—pressing becomes untraceable.

XIRO Electric Servo Press Solution:

Equipped with 16-bit strain-gauge force sensors (2kHz sampling) and real-time overload protection to react within 2ms, suppressing overshoot by >90%.

Three-Stage Force Control:

Pre-Contact: 5N preload to eliminate backlash and avoid dry hits.

Main Press: Constant force (20N ±0.3N) to target position, accommodating material creep.

Stress Release: Gradual unloading (18N → 15N → 12N) to reduce residual stress.

Overpressure Trigger: If force >22N, mold calibration routine activates within 2ms.

OK/NG Auto-Judgment: If force curve exceeds envelope, alarm triggers and workpiece is locked.

Results:

Overpressure risk reduced to 0.01%.

Curling rate of needle tips reduced to 0.

100% process traceability achieved.

XIRO electric servo press (Customizable)

Summary: XIRO Electric Servo Press Advantages

| Feature | Pneumatic Press | XIRO Electric Servo Press |

| Displacement Accuracy | ±0.1mm | ±0.001mm |

| Force Accuracy | ±10% FS | ±0.5% FS |

| Speed Control | 2–3 fixed steps | Stepless from 0.01–50mm/s |

| Data Recording | Result only | Full-process parameter logging |

| Energy Efficiency | Continuous air consumption | Power only during motion, high-efficiency |

Conclusion

Electric servo press machines—exemplified by the XIRO series—are redefining quality control in syringe needle assembly. With closed-loop control of displacement, force, and speed, along with intelligent algorithms and traceability, these press machines significantly improve consistency, safety, and production efficiency. They are setting new standards in advanced medical device manufacturing.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.