Battery module pressing is a critical step in the manufacturing of EV power battery packs (PACKs). The precision and consistency of this process directly impact the structural integrity and safety performance of the battery system. Traditional press machines, particularly hydraulic presses, have become increasingly inadequate due to poor pressure control, insufficient material adaptability, and lack of data traceability.

With the shift from "coarse mechanical assembly" to "precision manufacturing" in the new energy vehicle industry, XIRO’s electric servo press machine offers transformative upgrades across core battery module pressing challenges. This article examines three critical pain points and the advanced servo press solutions used to resolve them.

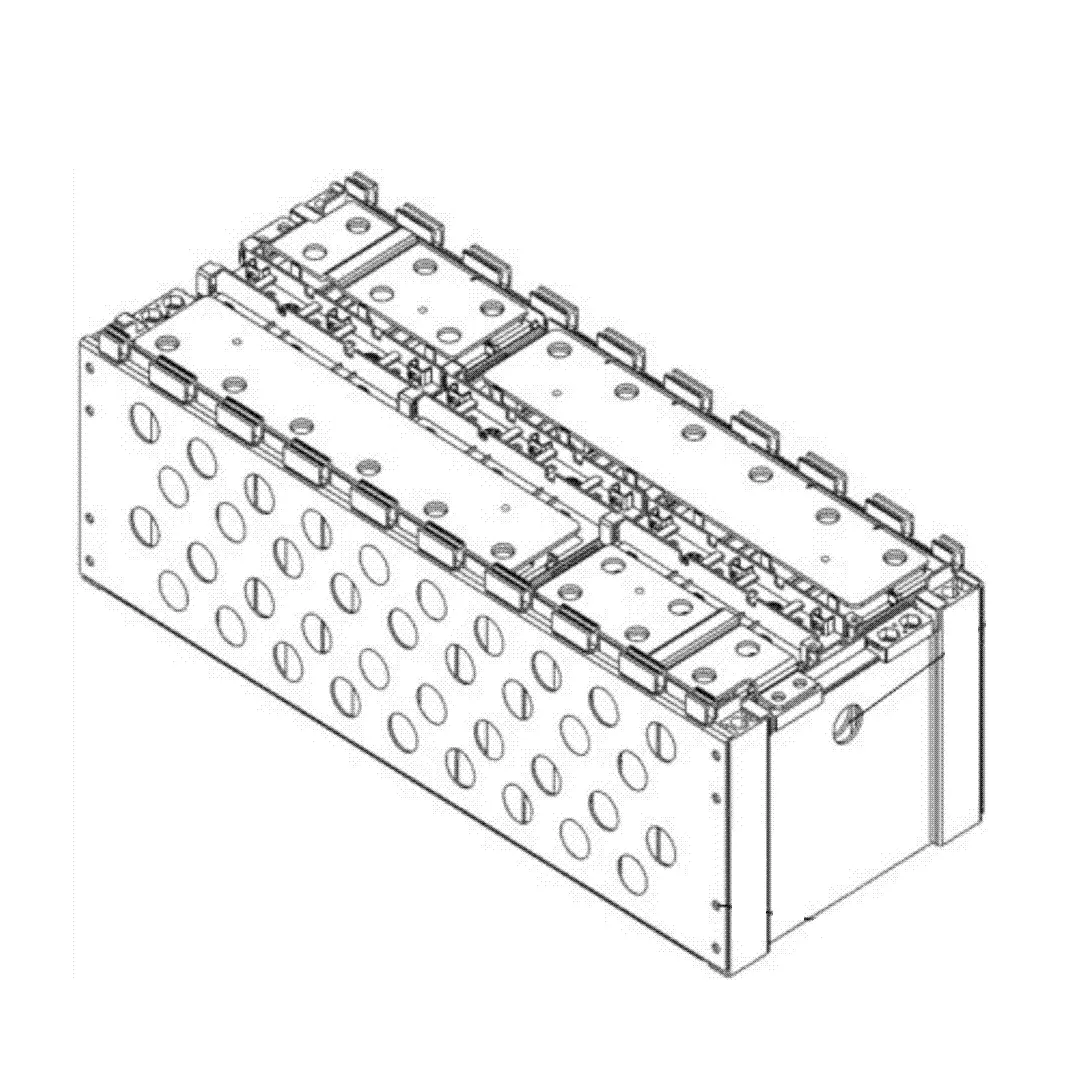

EV Battery Module

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Pain Point 1: Pressure Fluctuations Causing Cell Damage

Case Study

A major battery manufacturer encountered frequent microcracks in NCM811 prismatic cells during module pressing with traditional hydraulic presses. CT scans revealed cracks concentrated at the corners of the cell housing, reaching depths over 50μm. The pressing yield dropped to 91.5%, and cell lifespan was severely reduced.

Root Cause Analysis

1. Inaccurate Pressure Control

Hydraulic pressure fluctuations reached ±8%, causing localized stress concentration.

Valve response delay exceeded 50ms, leading to a 15% overshoot in peak pressure during fast pressing (e.g., 120mm/s), far beyond the allowable ±2N tolerance range for the cells.

Pressure sensors sampled at only 20Hz, missing millisecond-level surges (e.g., 3N increase within 5ms).

2. Material Fragility

NCM811 cathode compression strength is only 35MPa, while the aluminum shell yield strength ranges from 90 to 120MPa. Accurate pressure control within ±2N is essential.

High-nickel cells experience volumetric expansion >5% during charging cycles, which traditional pressing fails to compensate dynamically.

3. Delayed Quality Inspection

Random inspection cannot catch microcracks in real time. Defective cells can pass into the module, posing serious thermal runaway risks.

XIRO Electric Servo Press Solutions

1. Closed-Loop Pressure Control

24-bit high-precision pressure sensors (0.1N resolution) with 2000Hz sampling rate keep pressure fluctuation within ±0.3%.

PID algorithm dynamically adjusts pressure curve in real-time based on cell deformation feedback, effectively eliminating overshoot.

2. Custom Process Design

Pre-press stage uses infrared thermography to monitor cell temperature distribution, applying dynamic compensation (–0.5% pressure per +1℃).

Holding stage implements stepwise pressure release (–0.3N every 10s) to prevent rebound stress in high-nickel materials.

3. Full Process Traceability

Each cell generates a unique “process fingerprint” (pressure-displacement-temperature curve), integrated with the MES system.

Any data anomaly triggers an automatic stop, increasing mass production yield to 99.2%.

Pain Point 2: Stack Thickness Inconsistencies in Modules

Case Study

After 20,000km of road use, a blade battery-equipped EV showed a 0.5mm bulge on the battery enclosure. Inspection revealed that cell-to-cell gaps reached 0.8mm—2.7 times the design tolerance. Laser scanning confirmed that a deviation >0.5mm in terminal flatness dropped Busbar laser welding success rates from 99% to 83%.

(Note: Blade batteries feature ultra-long cells up to 1 meter and thickness as low as 0.3mm, equivalent to 3 strands of hair. Lamination accuracy must be within ±0.03mm for thousands of electrodes. Due to differing thermal expansion coefficients—aluminum shell: 23.1×10⁻⁶/℃ vs cell: 15×10⁻⁶/℃—a 5℃ rise can cause 0.035mm of interlayer gap accumulation.)

Root Cause Analysis

1. Process Control Limitations

Hydraulic press machines offer ±0.1mm repeatability; with ±0.01mm per sheet, stack deviation can accumulate up to ±1.6mm in extreme cases.

Rapid charging creates localized thermal gradients (>8℃), further exacerbating misalignment.

2. Material-Induced Errors

Separator film (25μm) rebound rate varies by ±8%, causing ±2μm per layer under 200kPa pressure.

6061-T6 aluminum shell exhibits creep, resulting in a rebound of 0.07–0.12mm after 24 hours of compression.

3. Lack of Real-Time Data Feedback

Conventional press machines only log peak pressure and final displacement—unable to detect live deviations or support traceability of defect origins.

XIRO Electric Servo Press Solutions

1. Dual Closed-Loop Control

Magnetic scale (0.1μm resolution) + servo encoder improve positioning repeatability to ±0.01mm.

2. Multi-Axis Compensation

X/Y/Z optical encoders + force sensors provide real-time correction of ram drift, ensuring high accuracy.

3. Temperature-Based Pressure Compensation

Infrared thermal imaging detects temperature gradients across cells; each +1℃ triggers a –0.5% pressure adjustment.

4. Smart Pressure Curve Monitoring

Second derivative analysis of the pressure-displacement curve identifies material yield points to avoid plastic deformation from overpressure.

5. Full Process Traceability

Every 5 layers in stacking trigger laser Z-axis scan (1μm resolution); results are sent to MES and matched with historical process data to avoid flawed pressure-speed combinations.

XIRO electric servo press (Customizable)

Pain Point 3: Module Sealing Failures

Case Study

During compression of 6061-T6 aluminum alloy side plates, microcracks were observed. Post 32,000 vibration cycles, the module exhibited a sealing failure rate of 12%.

Root Cause Analysis

Residual stress in the side plate reached 180MPa after pressing.

Bolt preload variation (±15%) caused localized stresses exceeding the material’s 275MPa yield strength.

| Parameter | Design Standard | Actual Range |

| Bolt Preload | 25 ± 1.5kN | 21.4–28.7kN |

| Side Plate Strain | ≤ 0.1% | 0.08%–0.25% |

XIRO Electric Servo Press Solutions

1. Three-Stage Precision Pressing

Pre-press (20kN): Hybrid force-displacement control eliminates gaps (±0.3% accuracy).

Main press (25kN): PID loop maintains 0.5s hold with stress fluctuation < ±1.5%.

Unload (5kN): Gradual pressure relief avoids rebound-induced deformation.

2. Structural Optimization

Insertion of a 0.5mm glass fiber + aramid fiber composite gasket between cell and side plate absorbs local stress peaks.

Stress concentration factor (Kt) reduced from 2.1 to 1.3, preventing microcrack propagation.

*Field Results

| Metric | Hydraulic Press | XIRO electric Servo Press |

| Side Plate Crack Rate | 8.7% | 0.4% |

| Pressing Cycle Time | 45s | 28s |

| Energy Consumption/Module | 3.2kWh | 1.8kWh |

Conclusion

As the EV battery industry evolves towards higher energy density and greater safety, the demands on press machines for precision, intelligence, and traceability have increased exponentially. XIRO electric servo press technology ensures consistent, traceable, and energy-efficient pressing solutions for modern battery production. It marks a shift from basic mechanical force to smart, software-defined manufacturing processes—paving the way for scalable, zero-defect battery module assembly.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.