In the fast-growing new energy industry, the positive and negative electrode connection process of power batteries has become a decisive factor for battery performance and safety. Traditional riveting methods often suffer from uneven riveting force, leading to microcracks (occurrence rate up to 15%) and false riveting (strength dispersion ±22%), directly reducing battery cycle life and thermal stability. For example, in 2024, a leading battery manufacturer reported that 37% of early module failures were caused by riveting defects, highlighting the urgent need for process upgrades. This article explains how electric servo press machines can break through the quality–efficiency–cost trade-off, offering a new paradigm for battery manufacturing.

Battery Electrode

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

1. Causes of Uneven Riveting Force Leading to Microcracks and False Riveting

Case 1: Dynamic Response Defects in Traditional Equipment

Hydraulic riveting systems can show up to 12% pressure overshoot with a 200 ms step signal. In one automotive chassis line, this fluctuation caused A286 rivet head height variation of 0.25 mm, creating stress concentration zones at the electrode base and increasing the risk of microcracks.

Case 2: Material Property Variation Amplifying Process Deviations

An EV battery housing made from 6061-T6 aluminum alloy exhibited batch-to-batch hardness variation (HB60–85), resulting in ±15% riveting force deviation during hydraulic riveting, and increasing sealing surface microcrack rate from 3% to 17%.

XIRO Electric Servo Press Solution

By converting servo motor rotation into linear force through a closed-loop control system, paired with a high-speed pressure sensor (0.01 ms response), XIRO servo press machines achieve ±1% pressure accuracy. The key lies in multi-stage pressure curve control and dynamic compensation algorithms to eliminate impact and improve riveting consistency.

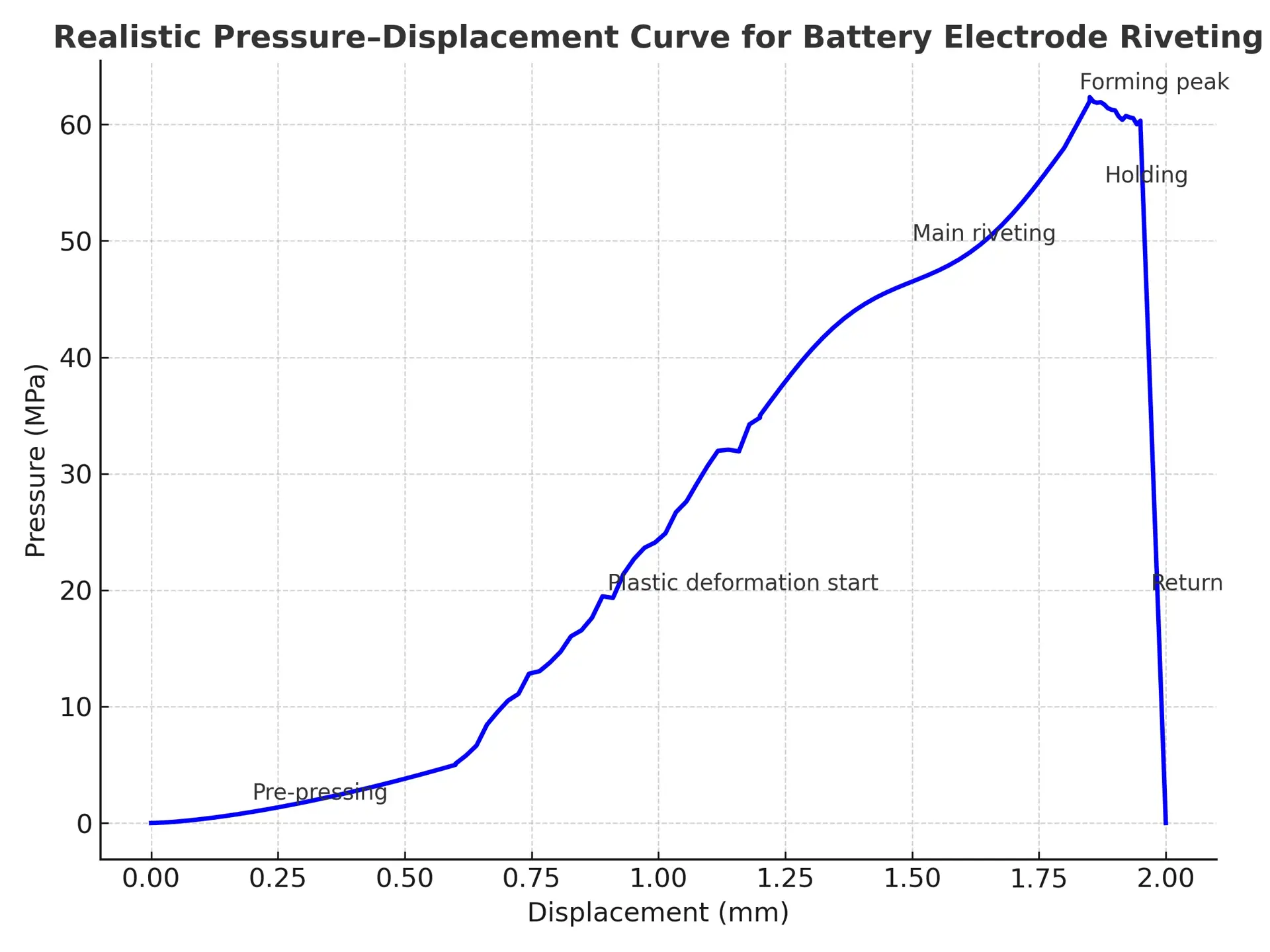

1. Multi-Stage Pressure Curve Control

-

Pre-pressing stage (20 MPa ±1%): Low-speed contact at 0.5 mm/s to detect initial hardness and eliminate gaps without causing impact displacement.

-

Main pressing stage (60 MPa ±0.5%): Plastic deformation at 3 mm/s, with real-time force gradient monitoring (dF/ds). If local hardening or abnormal yield is detected, the system automatically reduces pressure by 20% to avoid microcracks.

-

Holding stage (40 MPa ±0.3%, 1.5 s): Compensates for material springback to stabilize forming.

Note: Pressure settings can be dynamically adjusted according to electrode geometry, yield strength, and batch hardness to avoid thin-walled electrode damage.

Results (Lithium battery electrode riveting case):

-

Crack rate reduced by 97%

-

Springback reduced by 75%

-

Contact surface flatness significantly improved

2. High-Precision Displacement Control

-

Multi-axis coordination: Six-axis robotic arm positioning accuracy ±0.01 mm.

-

Thermal expansion compensation: Downstroke depth is dynamically corrected based on the material’s CTE (e.g., aluminum 23.6×10⁻⁶/°C).

Battery electrode riveting curve (Source: XIRO )

2. Challenges in Lightweight and Heat-Sensitive Materials

Case 1: Heat-Sensitive Material Processing Defects

During riveting, frictional work and plastic deformation generate heat. If the temperature exceeds 180 °C, resin matrices soften or degrade, leading to delamination.

In a UAV battery cover riveting project, the traditional process had a scrap rate of 22%.

Case 2: Composite Material Joint Failure

Due to differences in elastic modulus (aluminum 69 GPa vs steel 210 GPa), traditional riveting caused excessive deformation on the aluminum side, reducing joint strength.

XIRO Electric Servo Press Solution

1. Temperature–Pressure Coupling Control

-

Integrated infrared temperature module (100 Hz sampling) with PID algorithm. When temperature approaches the material’s critical threshold (e.g., resin Tg≈185 °C), the system automatically reduces pressure by 20% and increases coolant flow.

-

In a titanium alloy riveting case, the heat-affected zone depth was reduced from 1.2 mm to 0.3 mm.

2. Vibration Suppression Technology

Direct-drive linear motor keeps vibration acceleration under 0.05 m/s², preventing crack propagation in brittle materials like carbon fiber or ceramics.

3. Application Results

| Material Type | Traditional Process Issues | XIRO Solution | Improvement |

| TC4 Titanium Alloy | Force fluctuation reduced fatigue life by 40% | Strain rate control (0.001–0.01 s⁻¹) | Restored to 1.2×10⁶ cycles |

| Carbon fiber/Al mix | Interlaminar shear strength only 52 MPa | Ultrasonic assist + stepped pressure (60→80→60 MPa) | Strength ↑ to 78 MPa |

| PEEK molding parts | Cold creep deformation 0.15 mm oversize | Mold temperature control (165±2 °C) + low-speed press | Tolerance ±0.03 mm |

3. Efficiency Bottlenecks in Traditional Processes

Case 1: Mechanical Delay Causing Cycle Loss

Hydraulic riveting machines for battery electrodes have a theoretical 2.3 s/point cycle, but actual average is 3.1 s due to valve response delay and reset error.

Case 2: Fixed Process Limits Flexible Production

Switching from Φ3 mm electrode riveting to Φ8 mm busbar riveting requires parameter changes. Traditional machines take 47 minutes for retooling, losing 1,200 units of daily capacity.

XIRO Electric Servo Press Solution

1. Multi-Axis Speed Optimization

Six-axis robotic arm with 2000 Hz servo drive, achieving inter-point transfer speed of 1.5 m/s, reducing positioning time by 80%.

2. Quick Parameter Switching

Stores 100+ parameter sets, with<0.1 s recall time for different product specs.

3. Real-Time Quality Monitoring & Traceability

-

Force–displacement curve comparison within ±5% pressure, ±0.01 mm displacement tolerance.

-

Shape similarity analysis detects anomalies within 40 ms.

-

In a battery module line, airtightness yield improved from 95% to 99.8%.

-

All process data uploaded to MES for unit-level traceability.

Before vs After Retrofit (Battery Manufacturer)

| Metric | Hydraulic Riveting | XIRO Electric Servo Press | Improvement |

| Cycle time/point | 2.3 s | 0.8 s | 65% faster |

| Defect rate | 12% | 0.5% | 95% lower |

| Annual energy use | 12,000 kWh | 4,000 kWh | 67% lower |

| Tool change time | 30 min | 5 min | 83% faster |

Conclusion

Electric servo press provides a precise, flexible, and data-driven solution for battery electrode riveting. It not only overcomes hydraulic machines’ limitations in force control, material adaptability, and thermal management but also achieves simultaneous improvements in quality, efficiency, and cost. For the critical positive–negative electrode connection stage—directly impacting battery life and safety—XIRO electric servo press machine offers a proven, traceable, and industry-ready manufacturing solution.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.