Retaining rings are critical fastening components in mechanical transmission systems. The quality of retaining ring assembly directly affects bearing life, NVH performance of steering systems, and even the overall safety level of the equipment. Traditional hydraulic and pneumatic press machines face four key challenges: insufficient positioning accuracy, unstable force control, lack of process monitoring, and poor flexibility in production. With the rise of servo press technology, these pain points are being systematically addressed.

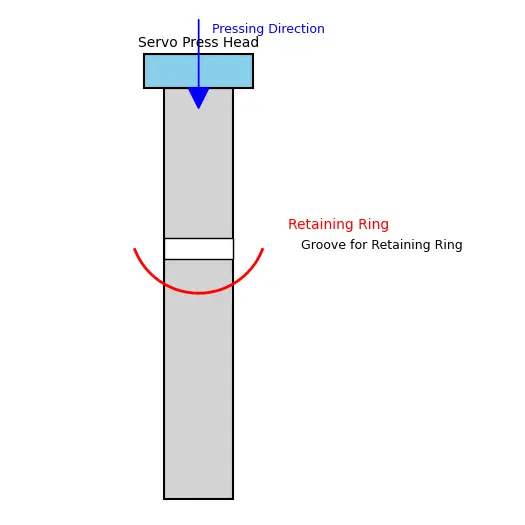

Retaining Ring Assembly

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

1. Positioning Accuracy: Eliminating Axial Misalignment

Case Study:

A motor manufacturer encountered issues when pressing retaining rings onto motor shafts. Due to ±0.1mm shaft length tolerances, traditional hydraulic press machines with fixed-stroke control caused 10–15% of retaining rings to remain partially out of the groove. This led to rotor axial movement, noise, and vibration failures.

Root Cause:

Fixed mechanical stops cannot compensate for part tolerances.

Manual adjustments introduce ±0.05mm errors.

Small part displacements (0.03mm) during clamping go undetected, leading to accumulated misalignment.

XIRO Electric Servo Press Solution:

Servo motor + ball screw + high-resolution encoder (0.001mm).

Micro-force detection (5–10N) switches to slow feed (0.1mm/s) at contact.

Final positioning accuracy within ±0.01mm, ensuring full groove engagement.

Results Comparison:

| Indicator | Hydraulic Press | XIRO Electric Servo Press | Improvement |

| Positioning Accuracy | ±0.3mm | ±0.01mm | 30× |

| Workpiece Damage Rate | 18% | 0.05% | 360× |

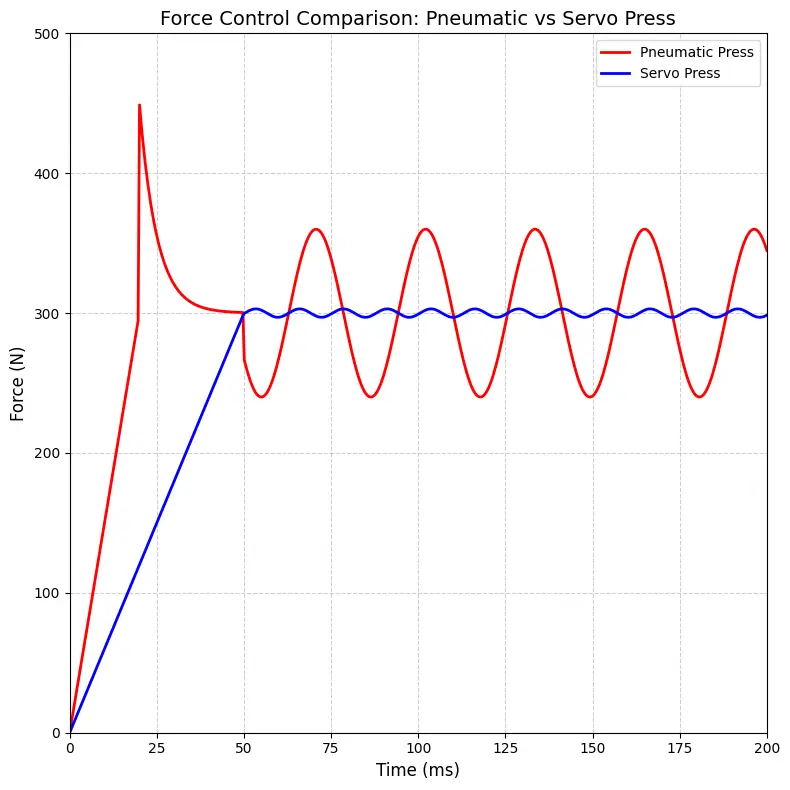

2. Force Control: Preventing Retaining Ring Deformation

Case Study:

On an automotive steering system assembly line, pneumatic press machines produced impact forces up to 150% of the set value (set 300N, peak 450N). The retaining rings deformed (Φ20±0.1mm → Φ20.35mm), losing axial locking capability and causing product recalls.

Root Cause:

No real-time feedback in pneumatic presses.

High-speed impact (200mm/s) caused peak forces up to 800N.

Valve delay (>100ms) failed to cut off power quickly.

XIRO Electric Servo Press Solution:

Servo control enables a three-stage press curve:

High-speed approach: 300mm/s before contact.

Buffer stage: 20mm/s controlled descent.

Constant force stage: Stable 300N, no overshoot.

Results Comparison:

| Indicator | Pneumatic Press Machine | Servo Press Machine |

| Contact Impact | >150% peak load | Smooth, no overshoot |

| Force Stability | ±20% | ±1% (with rigid fixture & stable temperature) |

| Power Cut-off Delay | 100ms | <5ms |

3. Process Quality: Real-Time Monitoring and Defect Prevention

Case Study:

A home appliance manufacturer pressed oil-impregnated bearings into motor housings with pneumatic presses. Due to lack of process monitoring, ~15% of assemblies contained micro-cracks (0.05–0.1mm), leading to lubricant leakage and shaft seizure during use.

Root Cause:

Only endpoint force recorded, with low accuracy.

Pressure sampling rate 10Hz, displacement resolution 0.1mm—too low to detect micro-defects.

XIRO Electric Servo Press Solution:

Full force-displacement curve monitoring.

Real-time abnormality detection within 20ms.

Process data storage and traceability via MES integration.

Results Comparison:

| Indicator | Traditional Press Machine | XIRO Electric Servo Press |

| Micro-crack Detection Rate | 8% (manual sampling) | 99.98% |

| Defect Interception Speed | >30 min (end-of-line inspection) | 20 ms |

| Process Data Storage | Endpoint force only | Full-process recording |

4. Flexible Production: Multi-Spec Retaining Ring Assembly

Case Study:

A leading home-appliance manufacturer needed to press five shaft diameters of retaining rings on the same production line (Φ8 / Φ10 / Φ12 / Φ15 / Φ18). With traditional hydraulic press machines, every product changeover required a full stop to:

Remove four sets of mechanical hard stops (32 bolts in total).

Replace the guide-post tooling (weight >80 kg, required an overhead hoist).

Readjust mechanical travel-limit switches (calibrated with a feeler gauge to ±0.3 mm).

Total changeover time: ~120 minutes per change.

Root Cause:

Traditional equipment relies on hard mechanical stops and dedicated tooling, making parameter adjustments inherently complex and slow.

XIRO Electric Servo Press Solution:

Parameterized program control with stored press curves.

Quick changeover by scanning part codes and calling stored parameters.

One machine for multiple products, minimizing tooling downtime.

Force Control Comparison: Pneumatic vs Servo Press

(Source: XIRO )

Conclusion

In conclusion, retaining rings are thin-walled elastic locking components that demand extremely high positioning accuracy and force stability during assembly. Traditional hydraulic and pneumatic press machines, relying on mechanical hard stops and open-loop control, often face issues such as incomplete seating, impact deformation, and lack of process traceability, making them unsuitable for modern high-precision manufacturing.

XIRO electric Servo press, on the other hand, address these challenges through closed-loop force–displacement control, high-precision position compensation, real-time monitoring, and flexible process switching. The key advantages in retaining ring assembly include:

Ensuring the retaining ring is fully seated in the groove, eliminating axial loosening risks.

Applying constant-speed insertion with constant-force locking, preventing deformation from impact loads.

Providing full-process data monitoring and traceability, reducing hidden defects and warranty risks.

Enabling quick changeovers between multiple specifications, supporting flexible manufacturing.

As a result, in applications such as automotive steering systems, motor shafts, and gearboxes, XIRO electric servo press are rapidly replacing hydraulic and pneumatic solutions, becoming the preferred technology for reliable and consistent retaining ring assembly.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.