In industrial automation and fluid control systems, the solenoid valve is a core actuator whose assembly quality directly impacts response speed, sealing performance, and service life. With industries such as new energy vehicles and medical equipment demanding increasingly high assembly precision, solenoid valve production involves multiple pressing operations: inserting the valve spool into the valve body, pressing the coil bobbin onto the iron core, fitting bearings and bushings, preloading and positioning springs, and pressing end caps and sealing covers.

These operations require extremely high standards for force accuracy, stroke control, speed profiles, positional precision, and process stability—requirements that traditional press machines often fail to meet.

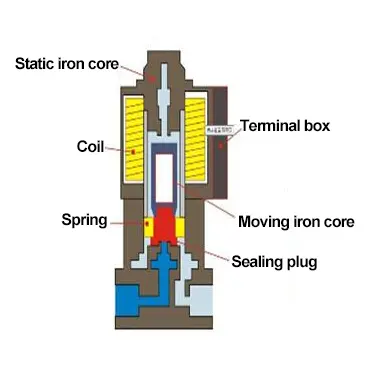

Diagram of Solenoid valve

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

1. Common Challenges in Traditional Press Machines

Challenge 1: Low Force Control Accuracy & High Fluctuation

Case Study:

A manufacturer using pneumatic presses to assemble spools with O-rings experienced a 15% failure rate during testing due to:

Excessive force (overshoot): Damaged O-rings led to internal leakage.

Insufficient force (undershoot): Incomplete spool insertion caused functional failures.

Root Cause:

Pneumatic systems are affected by air supply fluctuations, pipeline pressure loss, and friction variations.

Hydraulic presses face pump pressure fluctuations, oil temperature changes, valve response delays, and internal leakage.

Nonlinear friction transitions (static to dynamic), environmental vibrations, and micro-deformations of fixtures further destabilize force output.

Challenge 2: Uncontrolled Pressing Speed

Case Study:

On one production line, using a fixed-speed hydraulic press to press plastic coil bobbins onto iron cores resulted in an 8% breakage rate due to excessive initial speed causing tilting or cracking.

Root Cause:

Pneumatic cylinders typically rely on throttle valves for rough speed control, lacking precise speed curve programming.

Hydraulic systems offer limited variable speed control but respond slowly and are difficult to program.

Solenoid valve assembly requires different speed strategies for different phases:

Slow approach for alignment

Rapid motion during air stroke

Stable medium speed during interference fit

Deceleration before reaching final position to avoid impact

A single fixed speed cannot meet all these requirements.

Challenge 3: Inaccurate Position Control

Case Study:

Another manufacturer used mechanical stops and manual dial gauges to adjust spring preload. The actual compression deviation reached ±0.05 mm, causing the final valve actuation pressure to exceed customer specifications by ±10%, resulting in low batch qualification rates.

Root Cause:

Mechanical stops and simple limit switches offer poor repeatability (±0.1 mm or worse).

Wear in levers, screws, hydraulic cylinder creep, and backlash cause cumulative errors.

Part tolerance and fixture deviations cannot be compensated in real time.

Challenge 4: Lack of Process Monitoring & Quality Traceability

Case Study:

Random internal leaks were detected in final testing, but with no pressing data recorded, root-cause analysis was time-consuming. Eventually, microscopic burrs were found to have scratched O-rings during pressing, but traditional presses failed to capture the transient force spikes.

Root Cause:

No force-displacement (F-S) or force-time (F-t) curve recording.

No real-time quality judgment based on process parameters such as force windows, displacement windows, or slope monitoring.

Issues are only detected during destructive or offline testing, delaying troubleshooting and increasing rework costs.

2. XIRO Electric Servo Press Technology Advantages

1)High-Response Closed-Loop Force Control

Integrated high-precision force sensors directly measure real-time force at the press head.

Closed-loop control continuously compares measured force with target force profiles.

A feedforward + PID algorithm ensures rapid correction, with a control cycle ≤1 ms and sensor sampling rate ≥1 kHz.

Achieves ±0.5% F.S. force accuracy, preventing O-ring damage and incomplete insertions.

2)Multi-Stage Programmable Speed Profiles

Users can define multiple speed stages with triggers based on position or force thresholds (e.g., switch to low speed when force reaches 50 N).

Smooth S-curve acceleration and deceleration algorithms minimize mechanical shocks.

Enables optimal speed strategies for all assembly phases:

Fast air stroke → Slow contact alignment → Medium-speed interference fitting → Deceleration before final position → Dwell for stability

Significantly reduces coil bobbin cracking risks and improves cycle efficiency.

XIRO electric servo press (Customizable)

3)Dual Closed-Loop Force-Displacement Control

High-resolution encoders achieve ±0.01 mm positioning repeatability.

Force and position limits ensure both dimensional accuracy and overload protection.

Force-displacement curve monitoring detects hidden defects such as O-ring scratches or part deformation, enabling 100% in-process quality assurance.

4)Full Process Data Recording & Quality Traceability

Each pressing cycle records complete force-displacement-time data including:

Maximum force

Final force and position

Cycle time

Speed stage transitions

Data is stored locally or uploaded to MES systems for real-time analysis and quality tracking.

Engineers can review historical curves to pinpoint anomalies, eliminating blind troubleshooting.

3. Conclusion

XIRO servo press machines combine high-response closed-loop control, multi-stage speed programming, dual closed-loop force-displacement monitoring, and complete process traceability to address the critical challenges of solenoid valve assembly.

With these innovations, manufacturers achieve:

Higher product quality and consistency

Reduced scrap and rework rates

Increased production efficiency and flexibility

Full digitalization and traceability for smart manufacturing

For modern assembly lines, the XIRO servo press machine is not just a tool—it is a key enabler of precision automation, quality control, and Industry 4.0 transformation.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.