Shock absorbers are a core component of the automotive suspension system. The pressing quality of key components—such as piston rod assemblies, guides, oil seals, and base valves—directly determines the sealing performance, damping characteristics, NVH behavior, and service life of the shock absorber. The pressing process requires precise control of force and displacement (also known as press-in depth). Electric servo press machines enable real-time monitoring of the force–displacement curve, ensuring every component is assembled accurately and consistently on the automotive assembly line.

Automotive Shock Absorber

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Pain Points in Traditional Pressing Methods

1. Low Accuracy in Force and Displacement Control

Case: A supplier used a traditional pneumatic press machine to press piston rod guide seals for shock absorbers. Some seals were over-pressed, causing deformation or even damage (leading to potential leakage), while others lacked sufficient pressing force, resulting in initial sealing issues and oil leakage complaints after a period of driving.

Causes:

-

Pneumatic presses rely on compressed air, whose pressure fluctuates due to compressor performance, pipeline losses, and multiple devices using air simultaneously. Pressure variation can reach ±10% or higher.

-

The target pressing force was 2500N ±100N, but actual output fluctuated significantly between 2200N and 2800N.

-

The response speed of pneumatic valves is slow, making real-time precision adjustment of pressure impossible. Once pressing starts, it proceeds with full force, unable to adapt to resistance variations caused by part tolerances, burrs, or lubrication differences.

2. Risk of Misalignment or Jamming

Case: When pressing oil seals, minor burrs on the piston rod end or fixture misalignments as small as 0.1 mm caused sudden force spikes when rigid presses encountered these points. The seals' lips were often scratched or overturned, leading to decreased sealing performance. Operators sometimes misjudged this as "tight fit" and increased force, worsening the damage.

Causes:

-

Traditional presses use rigid connections between sliders or pistons and the pressing head, prone to slight tilts during operation.

-

Lack of real-time force–displacement feedback prevents detection of abnormal friction or resistance increases, relying solely on operator experience or brute force to complete pressing, risking damage to precision parts.

3. Lack of Process Data and Quality Traceability

Case: A batch of shock absorbers suffered oil leakage complaints. The traditional production line only recorded whether the "press-in place" light was on, without actual pressing force data or process curves. Engineers had to inspect parts individually—checking dimensions, seals, and glue processes-wasting time and failing to identify the root cause quickly.

Causes:

-

Traditional hydraulic equipment only recorded whether final force or displacement thresholds were met (pass/fail).

-

Without high-precision sensors, real-time pressure–position data and full process curves were unavailable, hindering accurate root cause analysis.

4. Limited Efficiency and Production Flexibility

Case: An automotive production line needed to switch between sedan and SUV shock absorber assemblies. Traditional hydraulic presses required stopping the line to manually replace press heads, adjust stroke limits, and reset pressure valves, taking 30–60 minutes each time. This severely limited efficiency and flexibility, making small-batch, multi-product production difficult.

Causes:

-

Heavy reliance on mechanical adjustments with low precision and cumbersome operations.

-

Limited motion control—hydraulic cylinders typically have only "forward/backward" modes with narrow adjustment ranges.

-

Lack of programmable press control—process parameters were hardcoded in hardware, making changeovers inconvenient.

XIRO Electric Servo Press Machine Solutions

XIRO electric servo press machines, powered by servo motors and integrated with high-precision sensors and advanced motion controllers, solve these pain points fundamentally:

1. High-Precision Force and Displacement Control

-

Closed-Loop Servo Control: Real-time feedback from high-resolution encoders and sensors enables the controller to adjust motor torque and speed dynamically, ensuring pressure accuracy of ±0.5% FS and displacement accuracy of ±0.01 mm, independent of external air or hydraulic fluctuations.

-

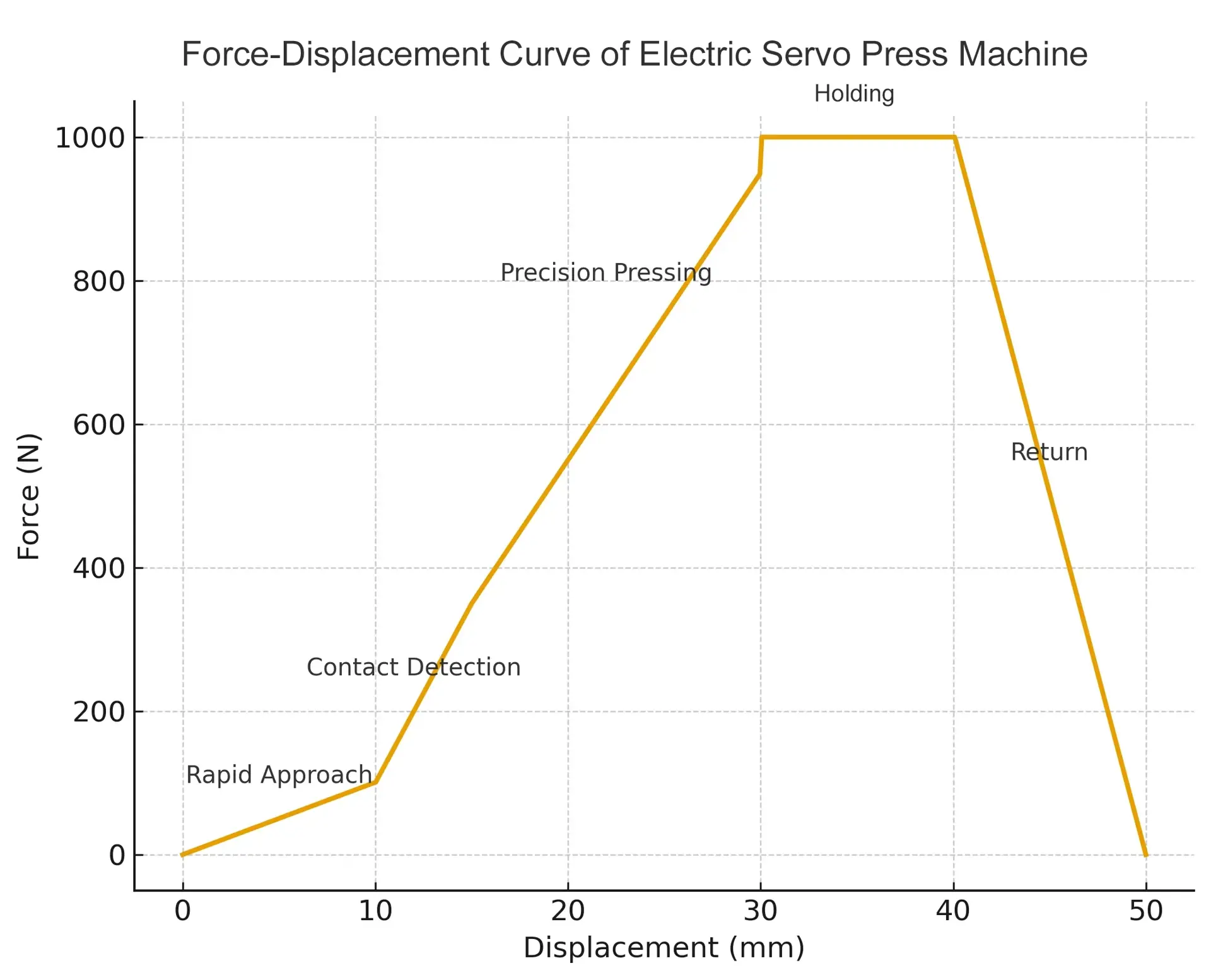

Programmable Multi-Stage Pressing Profiles: Different stages such as rapid approach, contact detection, pressing, holding, pressure release, and return can be customized. For example, rapid approach → low-speed contact detection → precise force or position pressing → holding for stabilization → controlled release.

2. Misalignment and Jamming Prevention

-

High Dynamic Response: Servo motors respond in milliseconds, detecting abnormal resistance increases and automatically slowing down, pausing, or retracting to avoid rigid impacts.

-

Real-Time Curve Monitoring: Force–displacement curves are continuously compared with preset qualification windows, identifying defects early (e.g., friction spikes, slope changes) for real-time rejection and traceability.

-

Adaptive Pressing with Floating Heads: Floating mechanisms with precision sensors allow the pressing head to self-align with the part axis, preventing unilateral friction and damage.

Force–Displacement Curve (Source: XIRO )

3. Full Process Data Acquisition and Traceability

-

Complete Curve Recording: Every pressing cycle's force–displacement curve, key parameters (max force, final position, holding force), and timestamps are stored, creating a digital fingerprint for each product.

-

Data Management and SPC Analysis: Integrated software enables data storage, SPC monitoring, alarm tracing, and root cause analysis for process optimization and predictive maintenance.

4. Enhanced Efficiency and Production Flexibility

-

Recipe-Based Control: Process parameters are stored as digital "recipes." Switching product models requires only selecting the corresponding program on the HMI, reducing changeover time from nearly an hour to just seconds.

-

Soft Start/Stop and Controlled Acceleration: Reduces mechanical impact, noise, and wear while improving stability.

-

Low-Cost Maintenance: Eliminates pneumatic/hydraulic components like air treatment units or oil pumps, reducing maintenance costs and environmental risks.

Conclusion

By integrating adaptive pressing technologies, real-time data acquisition, and programmable press control, XIRO electric servo press solutions address the core challenges of traditional pressing systems. These innovations deliver higher precision, better consistency, and full process traceability for automotive assembly lines, enabling manufacturers to achieve flexible, intelligent, and cost-efficient production. With electric servo press technology, shock absorber assembly reaches new levels of quality and efficiency, meeting the demands of industrial automation and smart manufacturing.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.