In the field of precision valve manufacturing, valve plate riveting has always been the core process that determines product performance. Traditional mechanical press machines, due to insufficient pressing accuracy, reliance on manual mold replacement, and operator experience, face several pain points such as long changeover time (more than 30 minutes per cycle) and significant production fluctuations (daily output reduction of up to 40%). These issues severely limit the ability to deliver diverse, small-batch orders.

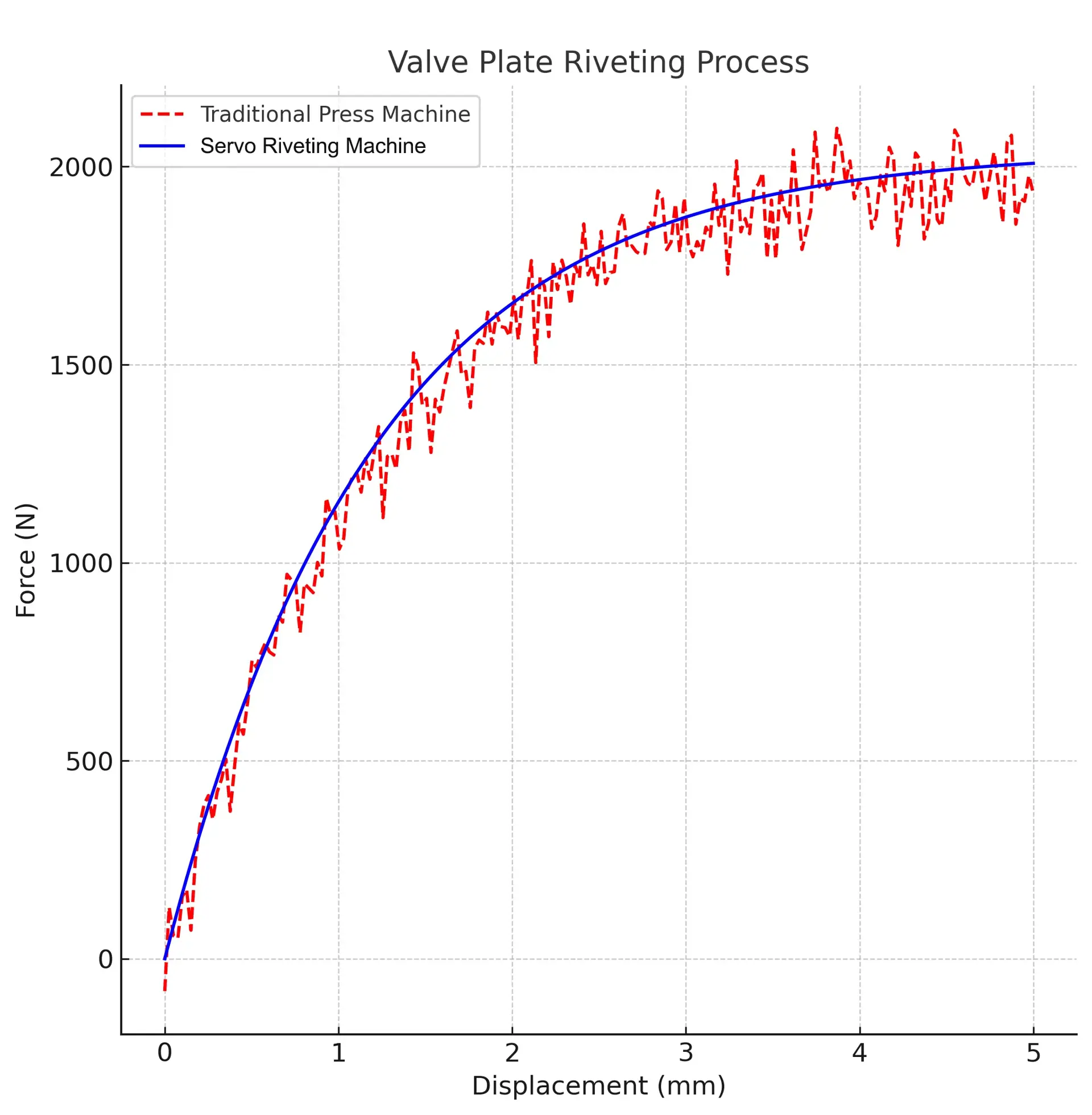

Force-Displacement Curve: Traditional Machine vs Servo Riveting Press

(Source: XIRO )

In recent years, electric servo riveting machines have addressed these challenges by adopting modular tooling design, digital parameter storage, and force-displacement closed-loop control technology. These improvements have increased changeover efficiency by dozens of times, raised process standardization close to 100%, and provided the industry with a solution that combines high precision and flexible manufacturing. This article analyzes typical shortcomings of traditional processes and presents servo riveting machine solutions, offering practical references for valve manufacturers aiming at smart factory upgrades.

Ⅰ. Common Problems in Valve Plate Riveting

1. Insufficient Pressure Control Accuracy

Traditional hydraulic or pneumatic press machines in valve plate riveting commonly suffer from large pressure fluctuations (typical variation ±5%), leading to two types of defects:

1) Overpressure: When actual pressure exceeds process requirements, the valve plate’s riveting area is prone to plastic deformation. For example, in an automotive parts factory, hydraulic press fluctuations caused an overpressure deformation rate of up to 8%, directly leading to sealing surface failure.

2) Underpressure: Insufficient force results in loose riveting. A home appliance manufacturer reported a 7% loose riveting rate due to hydraulic system pressure decay, leading to early leakage failures.

Root Causes:

Hydraulic system limitations: oil viscosity drift with temperature (approx. 3% per 10℃), seal wear leading to leakage (0.5–1.5 ml/min annually), feedback lag (proportional valve response >50ms).

Mechanical issues: gear pump flow pulsation (5–8%), pipeline pressure loss (0.3–0.5 MPa).

2. Inaccurate Position Control

Mechanical limit switches or stroke switches in traditional press machines often result in repeatability errors of ±0.1mm. This inconsistency directly affects the riveting depth of valve plates. In one home appliance case, deviations caused a 12% rework rate due to sealing failures.

Manifestations:

Excessive depth reduces sealing surface contact pressure, causing leakage.

Large batch-to-batch depth variations, harming consistency.

Root Causes:

Mechanical: backlash in screw/gear drives (0.05–0.2mm), wear-induced errors in limit switches (up to 0.2mm).

Control system: lack of closed-loop feedback, reliance on preset stroke only.

4. Poor Flexibility in Production

Traditional press machines face bottlenecks in flexible production:

1) Low changeover efficiency: switching valve plate models requires manual adjustment, over 30 minutes per cycle. A machinery factory reported 40% daily output loss due to frequent model changes.

2) Poor adaptability: different models require separate molds and settings, causing long preparation time.

3) High scrap during trial runs: up to 15% defective rate when debugging new valve plate processes.

Root causes: reliance on physical mold replacement, mechanical limiters with low adjustment precision (±0.1mm), manual parameter tuning without digital storage, and no rapid switching capability.

Ⅱ. Advantages of XIRO Electric Servo Riveting Machines

1. High-Precision Closed-Loop Control

Equipped with servo motor + ball screw drive (repeatability ±0.01mm, stable ±0.02mm in production), combined with high-frequency sensors and encoders, the servo riveting machine achieves accurate force-position matching.

Feedforward + PID algorithms compensate backlash in real time.

Multi-point calibration (10+ parameters available).

Automatic compensation for material elasticity during riveting, ensuring stable forming.

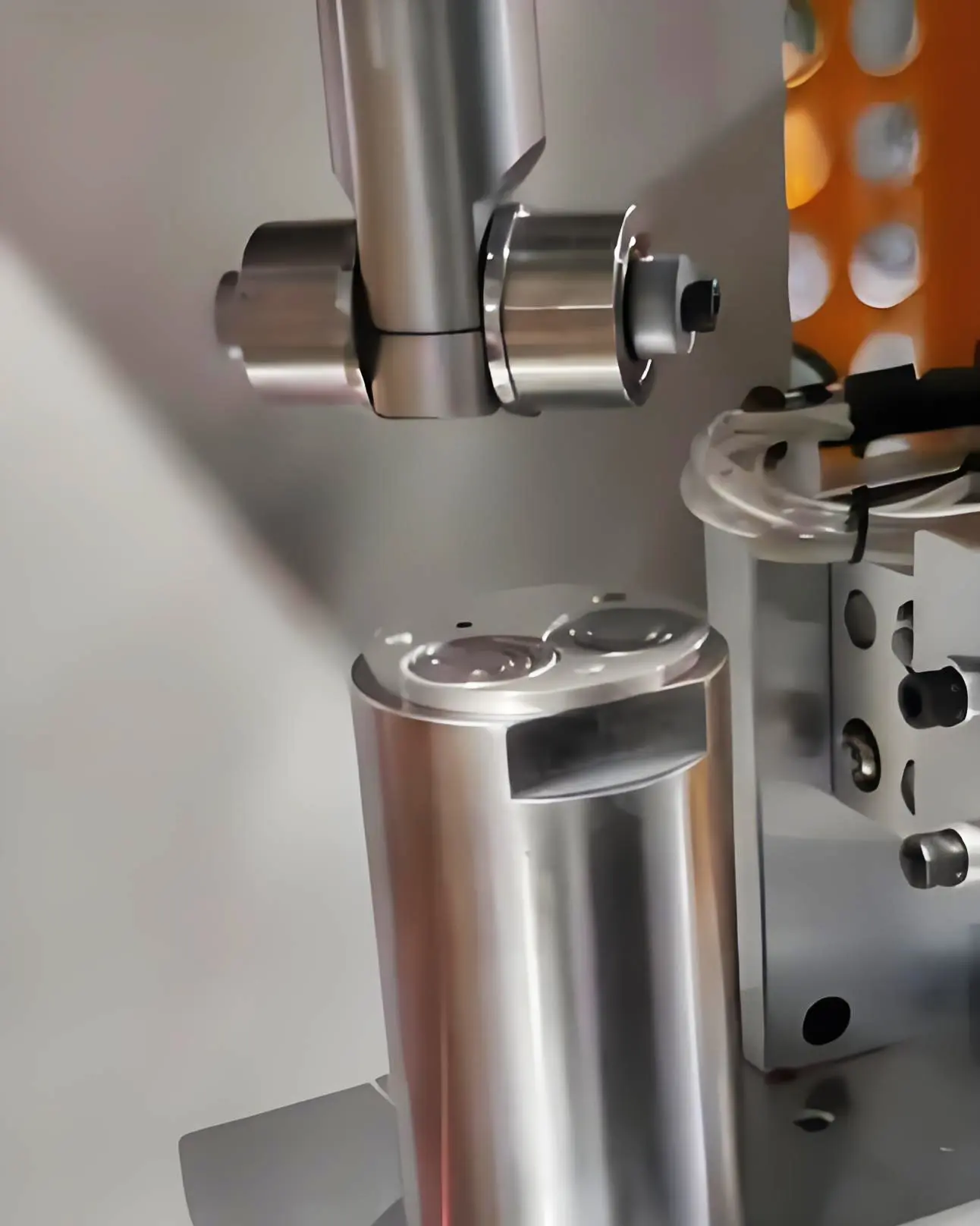

Valve Plate Riveting Process

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

2. Full Process Data Storage and Real-Time Monitoring

Real-time force-displacement curve display with automatic alarms on abnormalities.

Built-in high-precision acquisition stores ≥1000 process curves for complete quality traceability.

Seamless integration with MES/quality systems for batch management.

3. Flexible Manufacturing

Modular tooling reduces changeover time to within 1 minute.

Pre-stored 100+ riveting programs, one-click recall or RFID auto-identification.

Debugging new models efficiency improved by over 50%, scrap rate significantly reduced (from 15% to below 3%).

*Technical Comparison

| Index | Traditional Machine | XIRO | Improvement |

| Pressure Accuracy | ±5% | ±0.5% F.S. | ≥10x |

| Response Time | >50ms | <5ms | ≥10x |

| Data Traceability | None | Full-process storage | 100% cover |

| Changeover Time | 30min | 1min | ≥30x |

| Debugging Time | 8h/model | 1.5–2h/model | ≥60% faster |

*Case Study Results

After adopting the XIRO servo riveting machine, one automotive parts factory achieved:

Valve plate overpressure deformation reduced from 8% to<0.3%.

Loose riveting rate decreased from 7% to<0.2%.

Single changeover time shortened from 35 minutes to 1 minute, boosting productivity by 45%.

Complete process traceability enabled, cutting quality analysis from hours to minutes.

III. Conclusion

Valve plate riveting requires extremely high standards for pressure accuracy, position control, and process consistency. Traditional hydraulic/pneumatic press machines face inherent drawbacks such as fluctuations, insufficient accuracy, and lack of traceability, making them unsuitable for modern precision manufacturing and flexible production demands.

XIRO electric servo riveting machines, with their advantages of high-precision closed-loop control, complete data traceability, and rapid changeover, have become essential equipment for valve manufacturers pursuing intelligent upgrades and competitive advantage in global markets.

Discover how XIRO Electric servo press technology can help your production line reduce scrap, accelerate changeovers, and improve traceability. Contact us or visit YouTube channel to explore 100+ servo press applications demos across the automotive, aerospace, and precision manufacturing sectors.