With the rapid development of the UAV (Unmanned Aerial Vehicle) industry, the assembly quality of motor shafts directly determines flight performance and reliability. Traditional press machine processes face major challenges in UAV motor shaft assembly, including force fluctuation, insufficient displacement accuracy, difficulties in quality traceability, delayed overpressure/underpressure detection, and low efficiency in multi-specification changeovers. These bottlenecks seriously limit both product consistency and mass production efficiency in high-end UAVs.

UAV Motor

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Ⅰ. Pain Points and Root Causes of Traditional Pressing Methods

1. Force fluctuation leading to bearing damage

Case: In the batch production of an industrial UAV (shaft diameter φ6mm), hydraulic press machines showed force fluctuation up to ±200N due to oil temperature variations (±15℃) affecting viscosity. Around 3% of motors generated abnormal noise during testing. Post-disassembly revealed micro-cracks on the inner raceway of bearings, reducing lifespan by about 40%.

Root causes:

-

Shaft tolerance not well controlled (measured radial runout 0.08mm vs. 0.05mm design spec);

-

Hydraulic system response delay (~50ms) causing force overshoot, fluctuation ±18%;

-

Unstable pressing speed (set 10mm/s, actual 8–12mm/s);

-

Lack of real-time force compensation, causing local overpressure (up to 120% of design).

2. Insufficient displacement accuracy

Case: A military UAV required motor shaft coaxiality ≤0.01mm and press-fit depth of 15±0.02mm. Using mechanical press machines, measured depth fluctuated between 14.95–15.05mm, raising electromagnetic noise from 48dB to 52dB.

Root causes:

-

Mechanical limit wear (accuracy drop 0.1mm after 3 months);

-

Workshop temperature variation (±5℃) caused thermal deformation (elongation 0.03mm);

-

High-speed pressing inertia caused overshoot (0.05mm);

-

Lack of closed-loop displacement feedback.

3. Delayed detection of overpressure/underpressure

Case: In an agricultural UAV motor shaft assembly, low-frequency sensors (50Hz) with calibration errors failed to detect overpressure in time, causing batch scrapping.

Root causes:

-

Low sampling frequency;

-

No real-time force–displacement monitoring;

-

Lack of intelligent defect detection algorithms.

4. Difficulty in quality traceability

Case: A UAV manufacturer found 5% of motors with abnormal noise during mass production but could not trace issues back to specific batches.

Root causes:

-

Traditional press machines only recorded final force value;

-

No complete press-fit curve storage (unable to analyze pressing speed, force-displacement relation);

-

Production data not integrated with MES systems;

-

Manual recording prone to errors or omissions.

5. Low efficiency in multi-specification changeovers

Case: A UAV brand needed to produce both φ3mm and φ5mm shafts. Changing tooling required 35 minutes, reducing daily output by ~20%.

Root causes:

-

Fixed mold press machines required manual disassembly and repositioning;

-

First-piece yield after changeover only 80%.

Ⅱ. Key Technical Solutions of Electric Servo Press Machines

1. Full closed-loop force–displacement control

By using high-precision servo press machines with repeatability of 0.01mm, paired with ±0.5% F.S. pressure sensors and encoders, dual closed-loop control is achieved (≥1kHz sampling). With PID algorithms, shaft runout errors are dynamically compensated, ensuring stable pressing force and position accuracy.

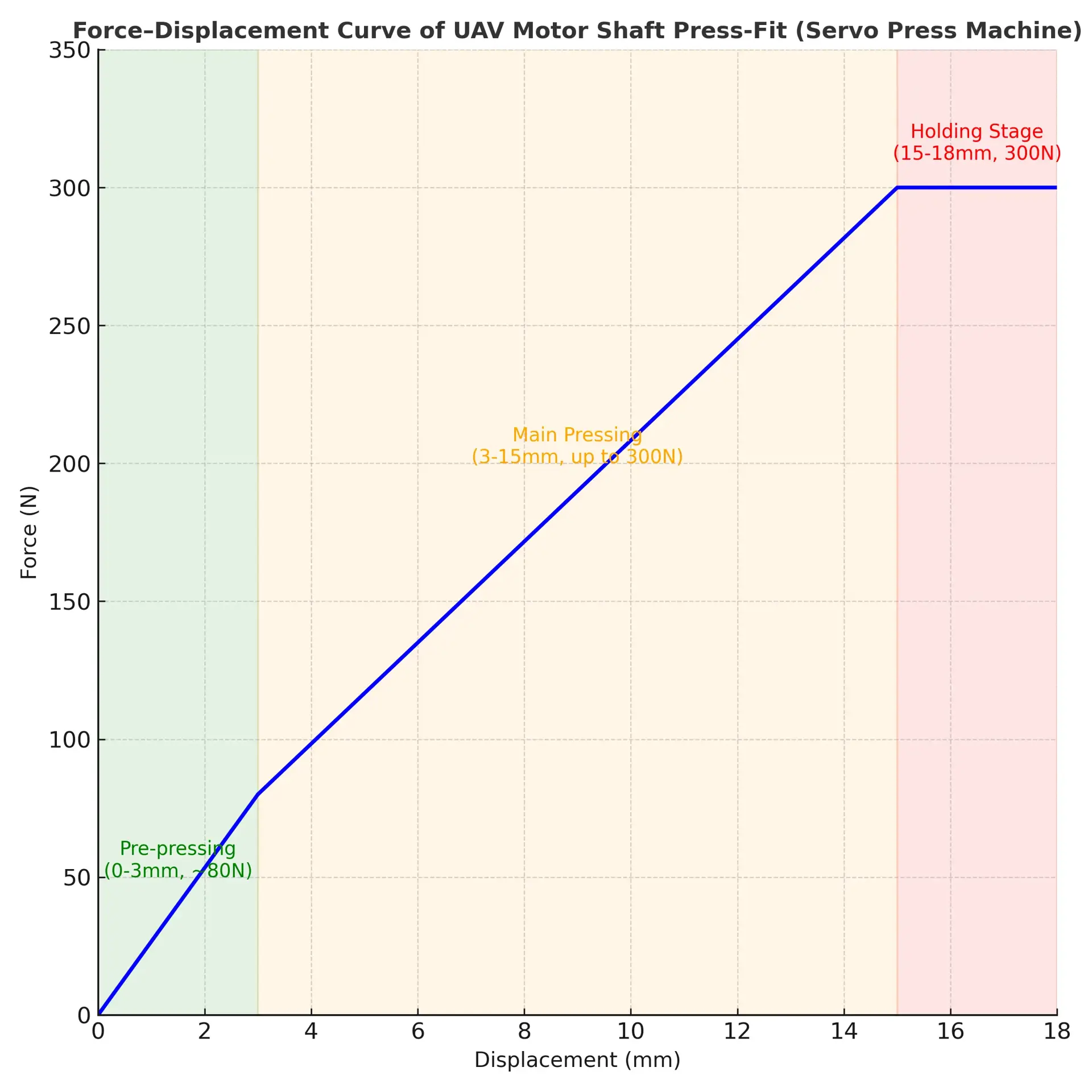

Force-Displacement Curve of UAV Motor Shaft Assembly

(Source: XIRO )

2. Three-stage pressing process

Programmable multi-stage press profiles with envelope monitoring and alarm response time <5ms provide precise control. For UAV motor shafts (e.g., aluminum alloy):

-

Pre-pressing (0–3mm): ~80N, speed 2–5mm/s, eliminate gaps;

-

Main pressing (3–15mm): ~300N, speed 0.5–1mm/s, ensure accurate deformation and coaxiality;

-

Holding stage (15–18mm): constant pressure for 3–5s, minimize creep and rebound.

3. Online quality judgment system

By recording force–displacement curves, real-time analysis of slope, force fluctuation, displacement rebound, harmonic features, and curve similarity ensures every motor shaft undergoes online qualification with automatic data storage.

4. Flexible tooling system

Quick-change fixtures: Magnetic positioning, pneumatic locking, and auto-centering pins reduce changeover time to 2 minutes;

Programmatic management: Storage of 100+ pressing programs with QR-code recall, eliminating manual parameter adjustments;

First-piece yield after changeover improved to 98%, supporting flexible UAV motor assembly across multiple shaft specifications.

Ⅲ. Implementation Results

A UAV enterprise adopted the XIRO electric servo press machine solution for motor shaft pressing:

-

Shaft axial clearance controlled to 0.01–0.03mm;

-

Yield improved to 99.2%;

-

Vibration improved as follows:

| Frequency Component | Before Improvement | After Improvement | Reduction |

| 1× frequency | 0.8g | 0.5g | 37.5% |

| 2× frequency | 0.3g | 0.15g | 50% |

These improvements also reduced noise by 3dB on average and extended bearing service life by ~25%.

Ⅳ. Conclusion

The application of XIRO electric servo press machines in UAV motor shaft assembly provides full closed-loop control, programmable multi-stage pressing, real-time quality judgment, and flexible tooling. These advantages eliminate the shortcomings of traditional press machines, significantly improving assembly accuracy, product consistency, yield, and production efficiency. For UAV manufacturers aiming at mass production of high-reliability drones, servo press machines have become a core technology to ensure long-term competitiveness and stable performance.