As the trend of new energy vehicles (NEVs) moves toward higher power density and lightweight design, the press-fitting quality of motor shaft steel tubes has become a key factor affecting the efficiency and reliability of electric motors.

EV Motor Shaft Steel Tubes

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Ⅰ. Challenges of Traditional Press-Fitting Methods

1. Insufficient Precision Leads to Unstable Assembly Quality

Traditional press machines driven by hydraulic or pneumatic systems have limited control accuracy and cannot achieve micron-level positioning. In EV motor shaft steel tube press-fitting, this lack of precision causes uneven interference fits, negatively impacting motor coaxiality and vibration characteristics, ultimately resulting in abnormal noise and shortened service life.

*Key press-fitting parameters directly affect assembly quality:

| Item | Control Range | Impact Analysis |

| Pressing Force | 50–200kN | Too low → loose fit; too high → thin-walled tube deformation |

| Pressing Speed | 0.5–2 mm/s (precision) | Too fast → impact risk; too slow → low efficiency |

| Dwell Time | 2–3 s | Ensures material contact and stress release |

| Parallelism | ≤0.03mm/100mm | Affects post-assembly coaxiality |

| Verticality | ≤0.03mm/100mm | Determines pressing direction accuracy |

2. Low Efficiency Impacts Production Cycle

Traditional press machines require manual parameter adjustments and operator supervision. Since press-fitting speed cannot be precisely controlled, mass production efficiency is significantly reduced.

3. Lack of Flexibility for Multi-Model Production

Parameter adjustments are complex, and tool changeover times are long. With the increasing variety of EV motor models, traditional press machines cannot quickly adapt to different shaft specifications.

4. Limited Quality Monitoring

Conventional press-fitting lacks real-time monitoring. Micro-cracks and incomplete fits are often detected only during later inspections, leading to costly production losses.

5. High Energy Consumption and Maintenance Costs

Hydraulic press machines face oil leakage risks, and their energy consumption is typically 3–4 times higher than that of servo press machines.

Ⅱ. XIRO Electric Servo Press Machine Solutions

1. High-Precision Closed-Loop Control System

-

Position Control: Servo motor + ball screw structure achieves ±0.01mm repeat positioning accuracy, ensuring consistent press-fitting depth.

-

Force Control: 0.5%FS force accuracy ensures stable interference fits, preventing over-pressing or under-pressing.

-

Parallelism Control: Ram-to-work surface parallelism ≤0.03mm/100mm, vertical accuracy ≤0.02mm/100mm, ensuring coaxial alignment of steel tubes.

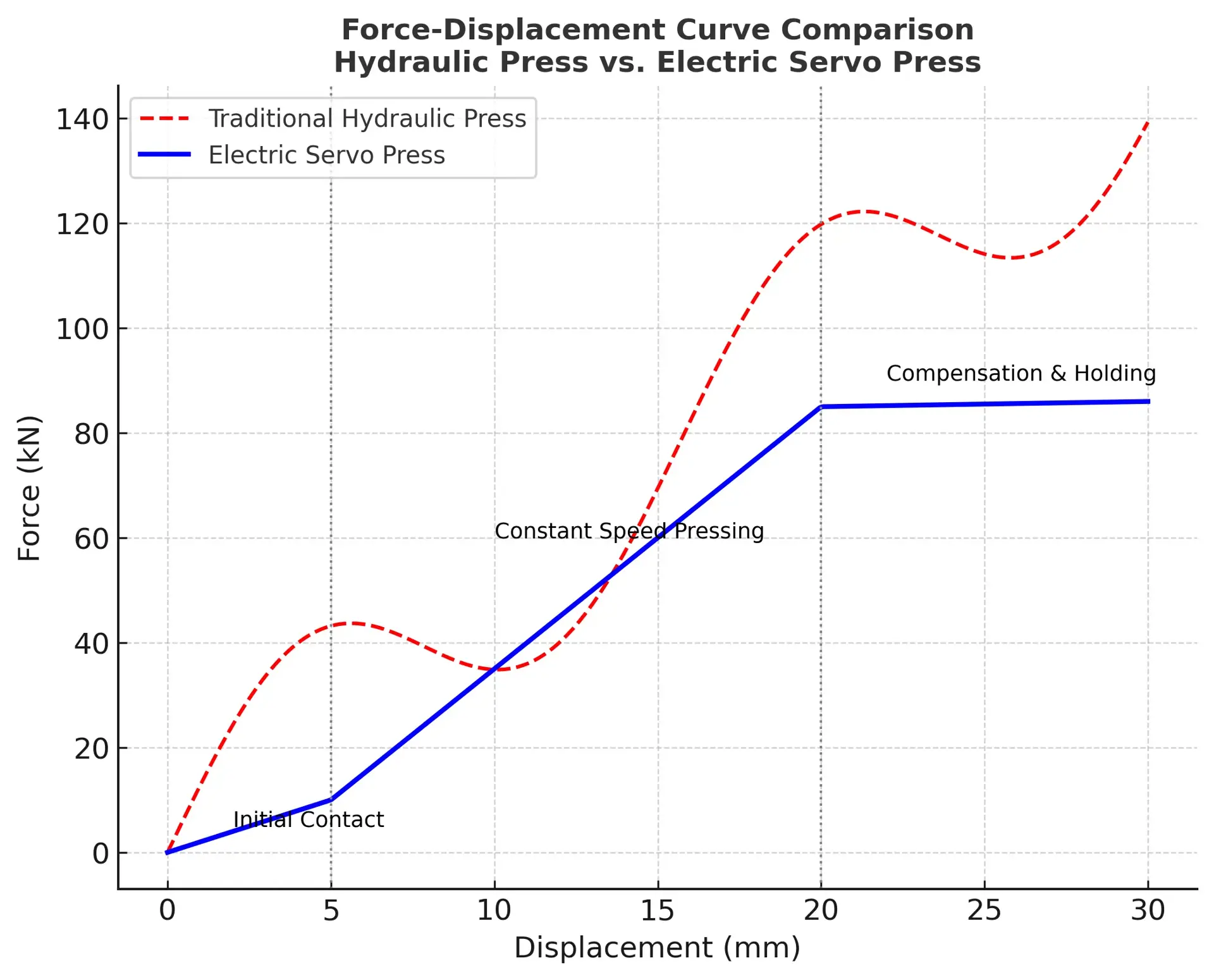

2. Three-Stage Press-Fitting Process

-

The servo press machine adopts a three-stage strategy:

-

Low-Speed Contact: Avoids initial impact and prevents deformation of thin-walled tubes.

-

Constant-Speed Pressing: Maintains stability throughout the process.

-

Final Pressure Compensation: Ensures optimal tightness and assembly quality.

Force-Displacement Curve Comparison: Hydraulic Press vs Electric Servo Press

(Source: XIRO )

3. Intelligent Process Monitoring Technology

-

Force-Displacement Curve Analysis: Real-time monitoring with window and envelope line algorithms to evaluate assembly consistency.

-

Abnormal Alarm System: Stops the press machine immediately if force/displacement anomalies are detected, preventing batch defects.

-

Data Traceability: Stores and exports all press-fitting data, supporting MES integration for full digital traceability.

4. Flexible Production Capabilities

-

Multi-Program Storage: Stores hundreds of press-fitting programs, reducing changeover time to under 5 minutes.

-

Parameter Adaptation: Automatically adjusts press-fitting curves according to material characteristics.

-

Modular Design: Enables quick tool and ram replacement, supporting diverse production needs.

5. High Efficiency and Energy Savings

-

Direct Drive Technology: Saves 77% energy compared to hydraulic systems, and 90% compared to pneumatic systems.

-

Fast Response: Acceleration time<0.1s, significantly improving production cycle.

-

Low Maintenance: Eliminates hydraulic oil leakage risks, reducing annual maintenance costs by 75%.

Ⅲ. Conclusion

The requirements for precision, efficiency, and reliability in EV motor shaft steel tube press-fitting continue to rise. Traditional hydraulic and pneumatic press machines struggle to meet the demands of thin-walled tube interference fits, coaxiality, and assembly consistency. XIRO electric servo press machines offer a superior solution. With closed-loop control, intelligent monitoring, flexible production, and energy efficiency, XIRO servo press machines not only solve the core challenges of conventional methods but also deliver digital, traceable, and high-quality press-fitting processes. This ensures the durability and high power density of next-generation electric vehicle motors.