In high-precision assembly processes such as aero-engine blade pins and automotive gearbox gears, the quality of pin press fitting directly determines the service life and reliability of the entire system. Traditional hydraulic press machines face critical limitations in control accuracy, flexible production, and data traceability, making them unsuitable for advanced manufacturing.This article analyzes the key process challenges in conventional press fitting and introduces the technical advantages of the XIRO electric servo press machine in precision pin assembly, offering an intelligent and data-driven manufacturing solution.

Steel Pin

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

Ⅰ. Common Pain Points in Traditional Press Fitting Processes

1. Insufficient Accuracy in Pressing Force and Depth Control

Case Study:

During the initial production phase of a German-brand 8AT gearbox, a 5.8% shifting delay defect was detected. Investigation revealed:

The designed protrusion height of the pin was 12.00±0.05mm, while the actual measurement fluctuated between 11.80~12.20mm (out of tolerance ±0.2mm).

The cumulative axial clearance exceeded 0.3mm, leading to asynchronous gear engagement.

Root Causes:

Hydraulic pressure fluctuation of ±12% failed to meet precision requirements.

Oil viscosity drift due to temperature variation caused 0.08–0.15mm displacement rebound during the holding phase.

Transmission backlash (0.05mm) and screw axial clearance (0.03mm) caused uncontrollable displacement up to 0.08mm.

Open-loop control led to normal-distributed deviation between actual and target displacement.

2. Failure to Detect Hidden Defects

Case Study:

A titanium bone nail product had a 3.2% fracture rate six months post-surgery. Investigation found a hole diameter deviation of 5μm, which resulted in a localized stress concentration up to 1200MPa, exceeding the material’s yield strength and generating microcracks invisible to the naked eye.

Limitations of Traditional Detection Methods:

Conventional press machines only record end-point pressure, ignoring dynamic process variations — miss rate up to 42%.

Without pressure–displacement curve analysis, sudden stress peaks (indicating microcracks) cannot be captured.

3. Workpiece Damage Due to Overtravel

Case Study:

In 2024, a smartphone manufacturer encountered large-scale deformation of antenna grooves in aluminum frames. During the pin press fitting process, the actual overtravel ranged from 0.12–0.25mm, exceeding the design tolerance of<0.03mm.

Root Causes:

Hydraulic valve delay ≥25ms and oil compressibility caused braking lag and impact inertia.

Insufficient rigidity of the frame (natural frequency<80Hz) led to resonance and overshoot.

Lack of Data Traceability

Case Study:

A German automotive brand experienced global recalls due to loose chassis pins. The root cause could not be traced because the production system lacked press-fitting data records.

Limitations:

No data storage or digital traceability function.

Manual recording introduced high error rates.

Difficulty in Flexible Production

Case Study:

A spacecraft structural component batch contained eight types of pin diameters (Φ3mm–Φ12mm). Traditional press machines required manual fixture changes, mechanical limit adjustments, and repeated trial pressing — making changeovers time-consuming.

Deficiencies:

Mechanical screw limit repositioning accuracy: ±0.3mm.

Manual locking torque fluctuation: ±15%, affecting clamping consistency.

Ⅱ. Core Technical Solutions of the XIRO Electric Servo Press Machine

1. High-Precision Closed-Loop Control System

The servo motor and high-precision ball screw (positioning accuracy ±0.01mm) achieve dual closed-loop control of force and displacement.

The pressure sensor (0.1% F.S. resolution) continuously monitors press force, while the grating scale (0.1μm resolution) tracks displacement in real time.

Combined with adaptive PID algorithms, the system compensates for position errors dynamically, ensuring depth accuracy within ±0.01mm and overtravel<0.01mm through an S-curve acceleration/deceleration profile.

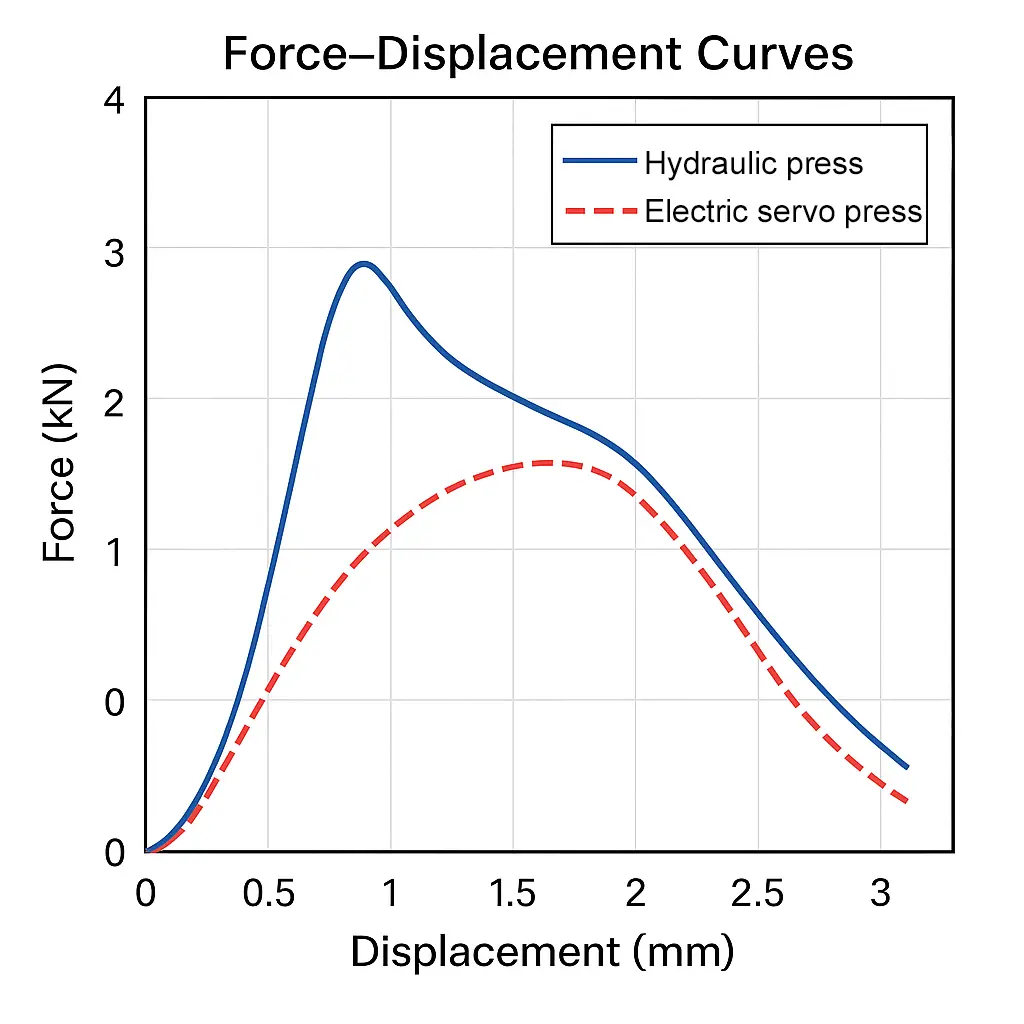

Steel Pin(Φ6mm) Press Fitting Curve: Hydraulic Press vs Electric Servo Press

(Source: XIRO )

2. Overtravel Suppression and Anomaly Detection Technology

The servo press machine analyzes the standard pressure curve characteristics (peak, slope, integral area) to detect sudden force increases or drops.

It evaluates slope change rate and area deviation to identify potential microcracks or hole-size anomalies, automatically triggering a deceleration command to adjust the press trajectory.

If the pressure exceeds 105% of the set value, the system cuts off the motor drive within 0.1ms.

A three-axis high-sensitivity accelerometer (±10g) monitors vibration and prevents structural resonance.

Implementation Results:

| Indicator | Traditional Press | XIRO Electric Servo Press | Improvement |

| Press depth repeatability | ±0.1mm | ±0.01mm | ↑ 90% |

| Pressure control error | ±5% F.S. | ±0.5% F.S. | ↑ 90% |

| Overtravel occurrence | 12% | 0.3% | ↓ 97.5% |

3. Full Data Traceability System

A high-frequency data acquisition module synchronously records force, displacement, and time. Each press-fitting curve is stored and linked with the MES system and product ID, achieving complete traceability and closed-loop quality control for every press fitting cycle.

4. Programmable Flexible Changeover

Using RFID identification, the press machine automatically recognizes the pin specification and loads the corresponding process program. A laser displacement sensor verifies fixture positioning accuracy in real time.

The system’s safety interlock logic prevents incorrect program loading. Traditional manual verification time is reduced from 30–120 minutes to within 90 seconds.

Implementation Comparison:

| Parameter | Traditional Process | XIRO Electric Servo Press |

| Press depth setting | Manual limit adjustment | Program preset |

| Press speed profile | Fixed | 4-stage programmable S-curve |

| Changeover time | 30–120 min | <2 min |

Ⅲ. Conclusion

XIRO electric servo press machine significantly enhances the consistency, accuracy, and reliability of precision pin assembly. Compared with conventional hydraulic press machines, servo press technology effectively eliminates issues such as poor control accuracy, overtravel, and undetectable defects.

Moreover, its intelligent monitoring, real-time data feedback, and flexible programmable control enable fully digitalized production, providing a quantifiable, traceable, and verifiable intelligent manufacturing solution for the aerospace, automotive, and medical industries.