Introduction

With the rapid growth of the new energy vehicle (NEV) industry, automakers are demanding lighter, quieter, and more reliable cooling systems. As a core component of the vehicle’s thermal management system, the assembly quality of the automotive cooling fan directly affects motor life and overall heat dissipation performance. However, most manufacturers still rely on traditional hydraulic or pneumatic press machines for assembly.

During the press-fit process between high-performance polymer composite materials (such as CFRP fan blades) and metal shafts, these legacy systems often suffer from insufficient press precision, long changeover time, and excessive energy consumption and maintenance costs.

Automotive Cooling Fan

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

To address these issues, the XIRO electric servo press machine introduces an integrated solution featuring full closed-loop force–displacement control, active cushioning technology, and a programmable electronic cam system. This innovation enables precise control, adaptive flexibility, and energy-efficient operation — representing a revolutionary process upgrade for large-scale manufacturing of automotive cooling fans in the NEV sector.

Ⅰ.Common Pain Points in Traditional Press Assembly

1. Low Pressure Control Accuracy → Component Damage or Failure

Case: A vehicle manufacturer experienced deformation in 30% of its cooling fan bearings due to ±15% hydraulic pressure fluctuation, resulting in abnormal noise and shortened service life.

Root Cause Analysis:

Hydraulic systems are affected by oil temperature and viscosity variation, leading to unstable pressure (typical fluctuation ±10–15%).

Pneumatic systems offer coarse pressure adjustment (minimum unit >1 bar), which fails to meet precision press-fit requirements for motor shafts and fan hubs.

2. Lack of Displacement Control → Assembly Depth Out of Tolerance

Case: A supplier required a retaining ring press-fit tolerance of ±0.1 mm but found actual deviations reaching ±0.5 mm, causing 10% of products to fail at 4500 rpm high-speed tests due to ring detachment and rotor interference.

Root Cause Analysis:

Mechanical stopper positioning suffers cumulative wear (wear rate >0.02 mm per thousand cycles).

No real-time position feedback, leading to uncorrected elastic deformation in plastic parts (≈0.1–0.3 mm).

3. Insufficient Flexibility → Low Changeover Efficiency

Case: A component plant producing five cooling fan models (200–400 mm diameter) required:

Mechanical adjustments: Replacing 15 mm-thick spacers (tolerance ±0.5 mm), manually calibrated with calipers (accumulated error ±1 mm).

Electrical tuning: Re-setting travel switches (delay 0.2 s) and recalibrating pressure sensors (zero drift ±2% F.S.).

Trial verification: The first three parts required micrometer testing (repeatability error 0.3 mm).

Result: Average changeover time per setup: 45 minutes (including 15 minutes downtime), leading to an annual productivity loss of 240 hours.

4. Impact Vibration → Damage to Precision Components

Case: A new energy vehicle manufacturer discovered microcracks 50–200 μm long (verified by SEM) in CFRP fan impellers assembled with pneumatic presses during annual production of 200,000 units.

Root Cause Analysis:

Electromagnetic valve switching within<10 ms caused instantaneous acceleration shock and stress concentration at the blade root.

Rubber pads provided passive damping (<15% leading="" to="" prolonged="" vibration="">0.5 s) and stress fatigue.

5. Energy Waste and High Maintenance Costs

Case: A German component factory reported:

Hydraulic system operating 16 hours per day, with 60% idle time (no-load power 3.2 kW); annual power consumption reached 350,000 kWh.

Hydraulic oil leakage up to 1299 L/year; sealing rings replaced eight times annually, with high maintenance cost per cycle.

Ⅱ.Technical Advantages of the XIRO Electric Servo Press Machine

1. Full Closed-Loop High-Precision Control

Triple-loop control architecture (current loop for torque, speed loop, and position loop) achieves force control accuracy of ±0.5% F.S. and displacement precision of ±1 μm via grating scale feedback.

Adaptive disturbance compensation algorithm adjusts in real time for material hardness variations.

Pressing force fluctuation <±2 N (vs. ±50 N in traditional systems), ensuring no deformation of bearings or fan blades.

Retaining ring press-fit depth accuracy up to ±0.05 mm.

2. Full-Process Curve Monitoring and Active Cushioning Control

1)Real-time monitoring:

The servo system collects continuous force and displacement data throughout the press-fit process (sensor accuracy ±0.1% F.S., resolution 0.1 μm), generating a real-time force–displacement–time curve.

2)Process evaluation:

Multiple monitoring windows can be configured — including contact point detection, force gradient analysis, final position tolerance, and peak force limits — to detect abnormalities such as part jamming, improper interference fit, or material fracture.

3)Active cushioning control:

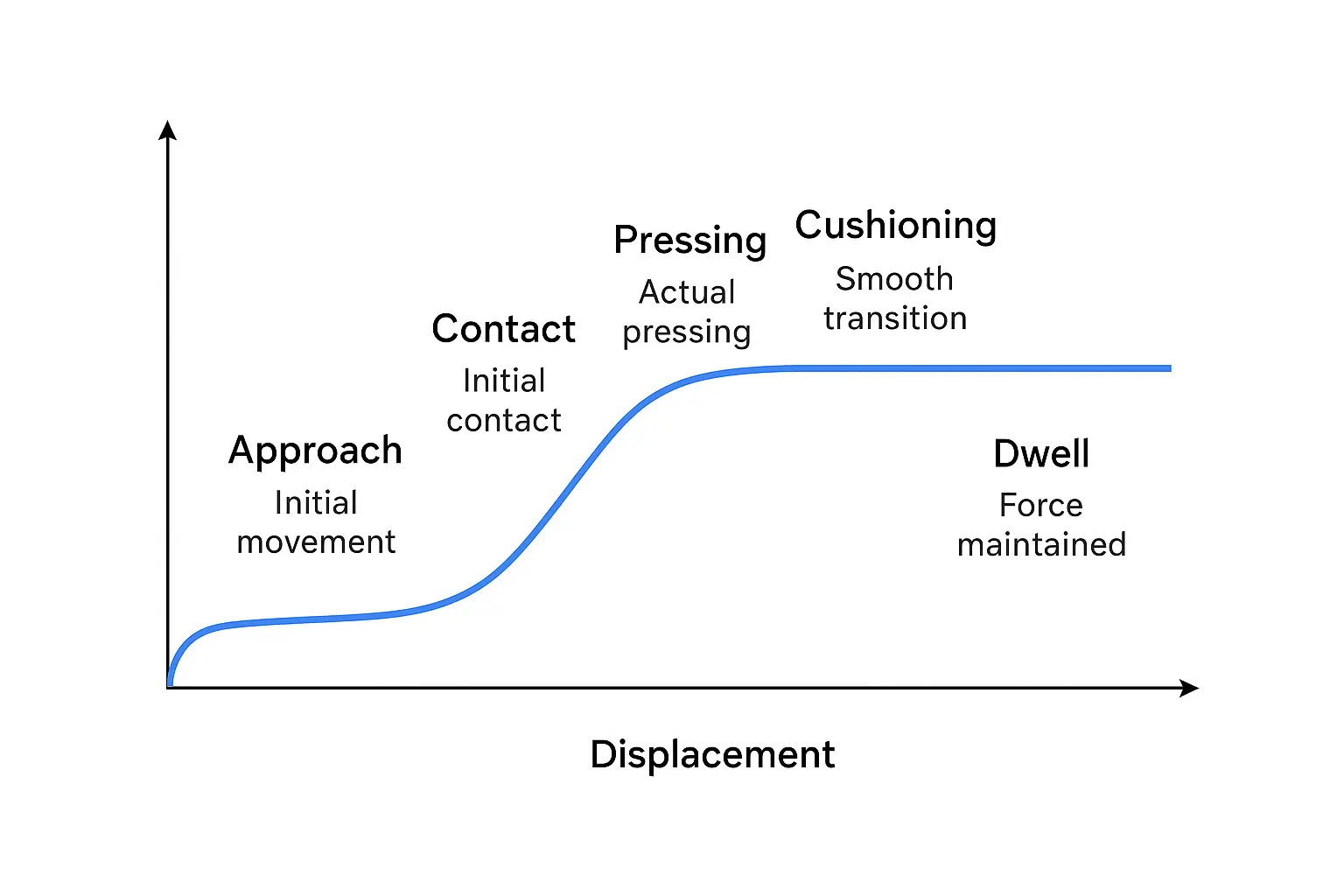

Electric servo press uses a five-stage S-curve motion profile (acceleration–constant acceleration–deceleration–constant deceleration–stop) to ensure smooth jerk transitions. Compared to traditional trapezoidal motion, this reduces impact force by 92%, lowering CFRP blade peak impact from 120 N to 15 N, as verified by SEM with no microcracks observed.

This technology effectively prevents stress concentration during the press-fit between lightweight plastic fan hubs and metal shafts.

Five-stage force–displacement control profile

(Source: XIRO )

3. Electronic Cam and Programmatic Flexibility

1) PLC-based recipe management system: Stores multiple parameter sets for force, displacement, and velocity curves, reducing changeover time from 45 minutes to ≤30 seconds.

2) Segmented variable-speed control:

Rapid approach and return improve production efficiency.

Low-speed initial contact protects delicate components.

Stable slow-speed main press ensures assembly precision.

Dwell phase guarantees proper seating and bonding.

4. Energy Saving and Low Maintenance

Direct-drive motor + ball screw configuration: Provides on-demand energy consumption, with standby power<50 W.

No hydraulic oil required: Eliminates oil leakage and contamination, ensuring a clean and quiet environment.

Simplified mechanical structure: Low failure rate, long service life, and maintenance-free operation rate >95% throughout the equipment lifecycle.

Ⅲ. Conclusion

XIRO electric servo press machine combines high-precision closed-loop control, active cushioning, and rapid flexible tooling changeover to fully resolve key assembly challenges in automotive cooling fan manufacturing — including deformation of metal bearings, microcracking of CFRP blades, and inefficient press-fit control.

Under the dual trends of lightweight design and green manufacturing, this servo press technology provides a scalable, intelligent, and energy-efficient assembly solution for the next generation of electric and hybrid vehicle cooling systems.