The assembly of automotive air conditioning (A/C) pipelines is a critical stage in vehicle manufacturing. The sealing reliability of these connections directly affects overall vehicle performance and user experience.

With the rise of new energy vehicles (NEVs), A/C systems now operate under more complex working conditions. However, traditional hydraulic or pneumatic press fitting processes suffer from limitations in precision control, dynamic response, and consistency.

Based on real industrial pain points and engineering practice, this paper analyzes how XIRO electric servo press machine achieves high-reliability assembly through closed-loop control, stress-field optimization, and adaptive parameter stabilization.

Automotive Air Conditioning Pipe

(For confidentiality purposes, the product images shown are representative illustrations only and do not depict actual client-specific product)

1. Common Pain Points in Automotive A/C Pipe Assembly

Pain Point 1: Micro Damage on Sealing Surfaces Leading to Refrigerant Leakage

Case: In a recall incident by a major German automaker, 23% of refrigerant leaks originated from traditional press fitting processes. Metallographic inspection showed micro-cracks on sealing rings due to stress concentration (crack density > 20 lines/mm²).

Cause: Conventional hydraulic/pneumatic presses often exhibit force overshoot (peak overshoot >15%). When an aluminum connector (HB 60) is pressed into an EPDM O-ring (Shore 70A), the impact force causes plastic deformation. Surface roughness above Ra 1.6 μm results in scratches deeper than 5 μm on the rubber surface.

XIRO Solution: XIRO electric servo press applies constant-speed contact and multi-stage force limiting control to ensure smooth contact and prevent instantaneous impact, significantly reducing sealing surface damage.

Pain Point 2: Mismatch of Multi-Material Deformation

Case: A new energy vehicle exhibited refrigerant leakage of 12g per year (5× the national standard) after a −30°C cold test due to material shrinkage mismatch.

Cause: A/C pipe assemblies combine aluminum tubes (CTE 23×10⁻⁶/°C), stainless-steel clamps (CTE 17×10⁻⁶/°C), and EPDM seals (CTE 180×10⁻⁶/°C). Under temperature variation, traditional constant-force pressing cannot compensate for thermal expansion differences, causing interface separation.

XIRO Solution: The servo press machine performs micro-displacement compensation and dynamic holding pressure control after assembly, automatically adjusting interface stress during thermal cycling to maintain long-term sealing reliability.

Pain Point 3: Assembly-Induced Stress Concentration

Case: A Japanese brand reported that 82% of cracks in 6061-T6 aluminum A/C pipe elbows were caused by residual assembly stress.

Cause: The complex geometry (e.g., 90° bends) and unidirectional pressing force of conventional presses lead to localized stress concentration. Finite element analysis revealed inner bend stress exceeding 120 MPa, beyond the material fatigue limit.

XIRO Solution: The servo press machine integrates force vector control and flexible floating fixtures, allowing adaptive pressing posture and smoother force flow paths, thus reducing stress concentration risk.

Pain Point 4: Parameter Drift in Traditional Systems

Case: In one plant, elevated ambient temperature caused a hydraulic system output drop. Over 2,000 A/C pipe joints were under-pressed by 0.2 mm, resulting in batch rework.

Cause: Oil viscosity fluctuation (Δη > 30%) and pneumatic pressure variation (±0.1 MPa) led to daily press-force drift >8%. At 3 kN pressing force, this equates to ±150 N variation.

XIRO Solution: The servo press system features a fully closed-loop electronic control with temperature compensation and dual-sensor feedback, maintaining force output stability within ±0.5%.

Pain Point 5: Stick-Slip Effect

Case: On a fully automated production line, stick-slip friction caused assembly yield to drop from 99% to 85%, losing 120 minutes per shift.

Cause: The rubber-metal interface friction coefficient shifted abruptly (static μ=0.8 → dynamic μ=0.3). Traditional machines couldn’t react fast enough, resulting in displacement oscillation (>0.05 mm).

XIRO Solution: The servo press employs high-frequency sampling (2 ms) and velocity closed-loop control, suppressing stick-slip-induced displacement fluctuations to as low as 0.01 mm for smooth pressing motion.

2. Key Technologies of XIRO Electric Servo Press

1) Three-Dimensional Closed-Loop Control

Sensor Layer:

Displacement: 24-bit absolute encoder tracks nonlinear creep and relaxation after O-ring compression.

Force: 0.5% F.S. pressure sensor detects real-time press fitting force and identifies micro surface irregularities.

Temperature: Non-contact IR sensor (±1°C) monitors key components, especially rubber seals.

Control Layer:

The hybrid of feedforward compensation and feedback correction ensures precision:

Proportional gain minimizes position error rapidly.

Integral gain eliminates steady-state error to maintain long-term sealing pressure.

Derivative gain predicts error rate change to suppress overshoot and vibration.

Control bandwidth >500 Hz enables a 2 ms “measure–compute–adjust” cycle for instant dynamic compensation.

Execution Layer:

A servo motor with a precision ball screw ensures rigid yet responsive transmission.

| Performance Metric | Traditional Press | XIRO Electric Servo Press | Improvement |

| Force Overshoot | >15% | <1% | 15× better |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | 4× smoother |

| Micro-crack Density | >20 lines/mm² | ≈0.3 lines/mm² | ↓98.5% |

| Leakage Rate | 12 g/year | <2 g/year | Near-zero leakage |

2) Stress Field Topology Optimization

A 6-axis force/torque sensor monitors multi-directional loads during press fitting. The built-in finite element algorithm (matrix iterative solver) calculates real-time stress distribution at >100 Hz, generating live stress maps and adjusting press trajectories to minimize force flow deviation.

In the digital twin module, assembly posture is optimized online, reducing maximum elbow stress from 120 MPa to 75 MPa and extending fatigue life by approximately 300%.

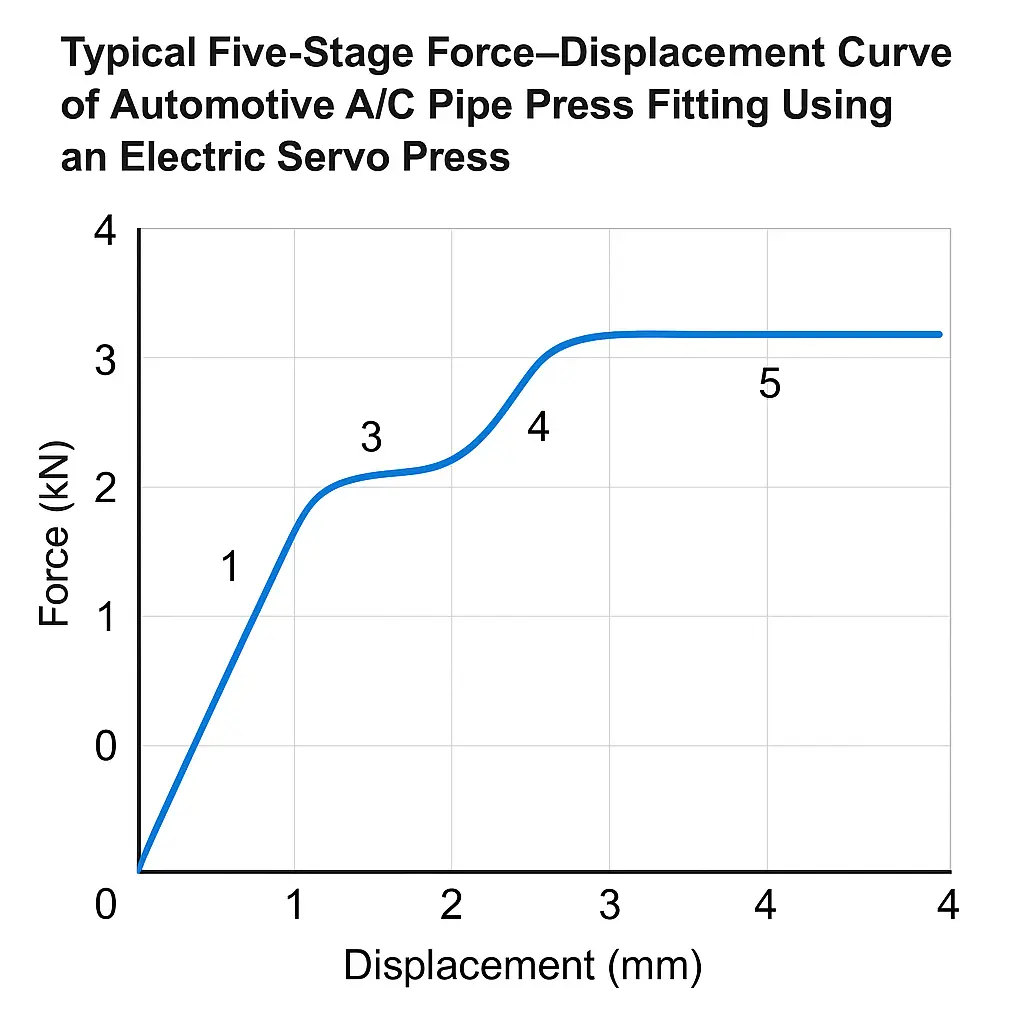

five-stage force–displacement control curve profile

(Source: XIRO )

3) All-Electric Drive and Adaptive Parameter Stabilization

Combining a servo motor, high-precision reducer, and ball screw transmission:

The system compares real force–displacement curves to standard reference data to detect performance degradation due to wear or lubrication changes, automatically tuning control parameters to maintain system stiffness.

Feedforward compensation proactively offsets known disturbances like gravity or static friction.

Dual-sensor comparison detects any abnormal drift to ensure accuracy and reliability.

| Performance Metric | Hydraulic/Pneumatic Press | XIRO Electric Servo Press |

| Daily Force Drift | >8% | <0.5% |

| Long-Term Position Accuracy | ±0.1 mm | ±0.01 mm |

| Stick-Slip Speed Fluctuation | >50% | <5% |

| Assembly Qualification Rate | 85% | 99.8% |

3. Conclusion

XIRO electric servo press machine leverages three-dimensional closed-loop control, stress field topology optimization, and adaptive parameter stabilization to resolve key challenges in automotive air conditioning pipe assembly — including sealing surface damage, stress concentration, parameter drift, and stick-slip effects.

In real-world applications, this servo pressing technology achieved near-zero leakage, 3× extended component lifespan, and >99.8% assembly qualification rate, while offering data traceability and predictive maintenance.